Nov . 17, 2024 06:04 Back to list

wooden h20 formwork manufacturer

The Role of Wooden H20 Formwork in Modern Construction

In the ever-evolving landscape of construction, the choice of formwork is a critical factor that can influence project efficiency, quality, and cost-effectiveness. Among various formwork solutions available today, wooden H20 formwork has distinguished itself as a reliable choice for builders and contractors globally. This article explores the characteristics, advantages, and applications of wooden H20 formwork, shedding light on its significant role in contemporary construction practices.

Understanding Wooden H20 Formwork

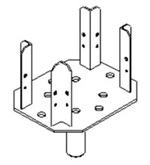

Wooden H20 formwork refers to a specific type of formwork system made from wooden components, particularly designed for pouring concrete. The “H20” designation usually indicates the dimensions of the beam used in the system, which is typically 20 cm in height. This formwork system is characterized by its lightweight yet robust design, allowing for ease of transportation and installation.

Key Features

One of the standout features of wooden H20 formwork is its structural integrity. The wooden beams are engineered to withstand the compressive forces exerted during the concrete pouring process, ensuring stability and safety. Additionally, the system is designed for quick assembly and disassembly, making it exceptionally time-efficient, which is crucial in today’s fast-paced construction environment.

Moreover, wooden H20 formwork can be customized according to various project requirements. The flexibility in dimensions and configurations allows contractors to create complex shapes and structures, thereby catering to unique architectural designs. This adaptability makes it a popular choice for various types of projects, including residential buildings, commercial structures, and infrastructure works.

Advantages of Wooden H20 Formwork

1. Cost-Effectiveness Wooden H20 formwork is often more affordable compared to other material options like steel or aluminum. Its lower material cost combined with the quick assembly time can significantly reduce overall labor costs.

wooden h20 formwork manufacturer

2. Sustainability Since wood is a renewable resource, using wooden formwork aligns with sustainable construction practices. Many manufacturers source wood from responsibly managed forests, which adds an eco-friendly attribute to using this formwork.

3. Ease of Handling Compared to heavier materials, wooden H20 formwork is considerably lighter, making it easier to handle and transport. This characteristic reduces the risk of worker injuries associated with heavy lifting and enhances overall site safety.

4. Reusability Wooden formwork systems can be reused multiple times, depending on how well they are maintained. This not only contributes to cost savings but also reduces waste on construction sites.

5. Quality Finish Wooden formwork can produce high-quality concrete finishes. The natural insulation properties of wood help regulate temperature and moisture levels during the curing process, which can lead to better overall concrete quality.

Applications of Wooden H20 Formwork

Wooden H20 formwork is highly versatile and can be used in a variety of applications. It is commonly employed in

- Foundation Works Its structural strength makes it ideal for supporting heavy loads, providing a sturdy framework for foundations. - Slabs and Decks Contractors often use H20 formwork for floor slabs, where a large surface area needs to be covered efficiently. - Walls The adaptable nature of H20 beams makes it suitable for forming concrete walls of different heights and thicknesses. - Infrastructure Projects Wooden H20 formwork is frequently used in bridges, tunnels, and other public works where durability and precision are paramount.

Conclusion

As the construction industry continues to embrace innovative solutions, wooden H20 formwork stands out as a practical choice that balances performance, cost, and sustainability. Its inherent advantages make it an appealing option for various projects, allowing builders to achieve structural integrity while staying within budget and timelines. As manufacturers continue to enhance their designs and production methods, the future of wooden H20 formwork looks promising, ensuring its place in modern construction practices.

-

Heavy Duty Props EN1065 Certified - Adjustable Steel Shoring for Formwork

NewsJul.21,2025

-

Heavy Duty Tripod & Fork Head: Stable Camera Mount for Pro Shots

NewsJul.21,2025

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025