feb . 04, 2025 05:51 Back to list

Column formwork

OEM inclined formwork systems have become integral to modern construction projects that aim for efficiency, precision, and safety. With years of experience and expertise in this field, we dive into how these systems stand out as indispensable components in the fast-paced construction sector.

The authoritativeness of OEM inclined formwork systems is backed by compliance with international construction standards and regulations. These systems undergo rigorous quality control measures and are often endorsed by leading civil engineering bodies and construction associations. Such endorsements provide assurance to project managers and architects regarding the reliability and durability of the formwork, thus instilling confidence throughout the supply chain. Trustworthiness stems from a track record of safety and performance. Companies that provide OEM inclined formwork systems often have extensive histories filled with successful deployments in diverse projects globally—from skyscrapers to intricate bridge constructions. Testimonials from clients and case studies highlight consistent problem-solving capabilities and adaptability in various environmental conditions. Moreover, these systems are designed with sustainability in mind, seeking to minimize waste through reusable components and longer life cycles. Sustainable practices in construction not only enhance the public perception of a project but also align with global initiatives towards reducing the industry's carbon footprint. In conclusion, OEM inclined formwork systems represent a fusion of experience, expertise, authoritativeness, and trustworthiness in construction innovation. Their impact is significant, offering a reliable solution that addresses the industry's call for safer, quicker, and more cost-effective building methods. As construction projects continue to grow in complexity and scale, these systems will remain at the forefront, steering the industry towards a future of advanced precision and sustainable practices.

The authoritativeness of OEM inclined formwork systems is backed by compliance with international construction standards and regulations. These systems undergo rigorous quality control measures and are often endorsed by leading civil engineering bodies and construction associations. Such endorsements provide assurance to project managers and architects regarding the reliability and durability of the formwork, thus instilling confidence throughout the supply chain. Trustworthiness stems from a track record of safety and performance. Companies that provide OEM inclined formwork systems often have extensive histories filled with successful deployments in diverse projects globally—from skyscrapers to intricate bridge constructions. Testimonials from clients and case studies highlight consistent problem-solving capabilities and adaptability in various environmental conditions. Moreover, these systems are designed with sustainability in mind, seeking to minimize waste through reusable components and longer life cycles. Sustainable practices in construction not only enhance the public perception of a project but also align with global initiatives towards reducing the industry's carbon footprint. In conclusion, OEM inclined formwork systems represent a fusion of experience, expertise, authoritativeness, and trustworthiness in construction innovation. Their impact is significant, offering a reliable solution that addresses the industry's call for safer, quicker, and more cost-effective building methods. As construction projects continue to grow in complexity and scale, these systems will remain at the forefront, steering the industry towards a future of advanced precision and sustainable practices.

Next:

Latest news

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

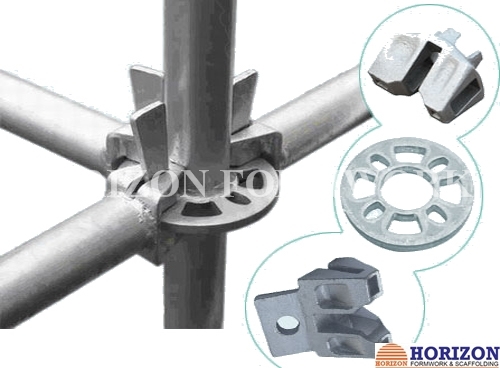

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025