Jul . 27, 2024 22:05 Back to list

Innovative Manufacturing Solutions for Scaffolding Jack Heads in the Construction Industry

The Scaffolding Jack Head Factory A Crucial Component in Construction

In the ever-evolving landscape of construction, safety and efficiency are paramount. One of the unsung heroes behind the scenes is the scaffolding jack head, an essential element that provides stability and support to structures under construction. The manufacturing of scaffolding jack heads has become a specialized industry, with factories dedicated to producing these critical components to meet the demands of modern construction projects.

Understanding Scaffolding Jack Heads

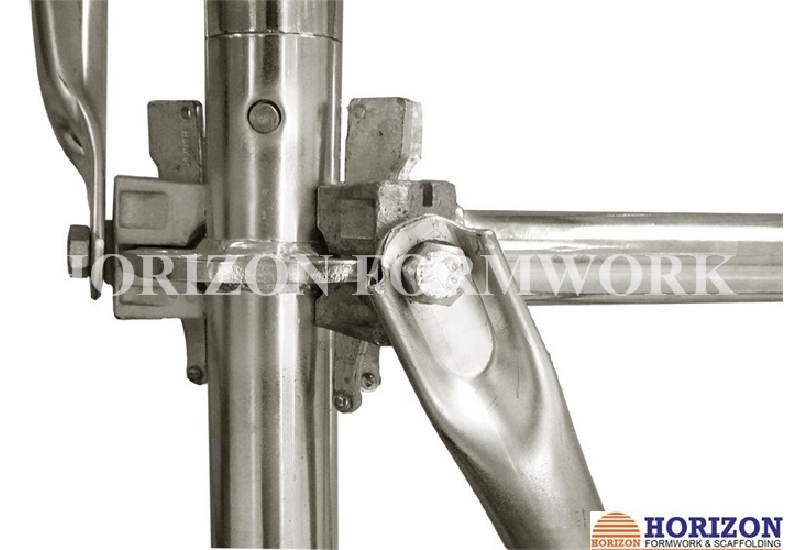

Scaffolding jack heads are devices used at the top of scaffolding columns to support the platform and allow for height adjustments. They ensure that scaffolding is securely fastened, preventing accidents and ensuring that construction workers can operate safely at various heights. These jack heads must withstand considerable load and resist tipping or collapsing under pressure, which makes their design and manufacture a meticulous process.

The Process of Manufacturing Scaffolding Jack Heads

The production of scaffolding jack heads begins with rigorous research and development. Engineers must consider several factors, including load-bearing capacity, materials, and environmental conditions where the scaffolding will be used. The most common materials used for manufacturing jack heads are high-strength steel and aluminum, chosen for their durability and lightweight properties.

The manufacturing process itself typically involves several stages

1. Material Preparation Raw materials are sourced and prepared for molding or machining. Quality control at this stage is crucial to ensure that the materials meet industry standards.

2. Forging and Machining The prepared materials undergo forging, shaping them into the basic form of the jack head. This is followed by precision machining, where exact dimensions and features are cut and formed.

scaffolding jack head factory

3. Heat Treatment To enhance the strength and durability of the jack heads, they are often subjected to heat treatment. This process alters the physical and sometimes chemical properties of the material, making it more resilient to wear and stress.

4. Finishing After machining, jack heads go through a finishing process that includes coating to prevent corrosion and increase longevity. This may involve galvanizing, powder coating, or painting.

5. Quality Assurance Each batch of jack heads is rigorously tested for safety and performance standards. This might involve load testing and inspection for any defects before they are released for sale.

The Importance of Quality Control

In the scaffolding industry, the stakes are incredibly high. Flaws in scaffolding components can lead to catastrophic failures, endangering the lives of workers. Therefore, quality control is not just a regulatory requirement but a moral imperative. Factories must adhere to strict standards set by organizations such as the Occupational Safety and Health Administration (OSHA) and international standards for safety and reliability.

Challenges in the Industry

Despite the critical role that scaffolding jack head factories play, they face several challenges. Market fluctuations, supply chain disruptions, and increasing competition can impact production capacities and costs. Furthermore, as construction projects become more complex and demanding, the need for innovative designs and materials continues to grow. Factories must be agile, adopting new technologies like automation and computer-aided design (CAD) to stay competitive and meet the evolving needs of their clients.

Conclusion

The scaffolding jack head factory is a vital player in the construction ecosystem. Through a combination of engineering, craftsmanship, and rigorous testing, these factories produce components that ensure safety, stability, and efficiency on construction sites. As the construction industry continues to advance, the importance of high-quality scaffolding jack heads and the factories that manufacture them will remain indispensable in building a safer and more resilient infrastructure. It’s a blend of precision engineering and a commitment to safety that defines this crucial manufacturing sector.

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025