Dec . 03, 2024 12:26 Back to list

steel formwork factory

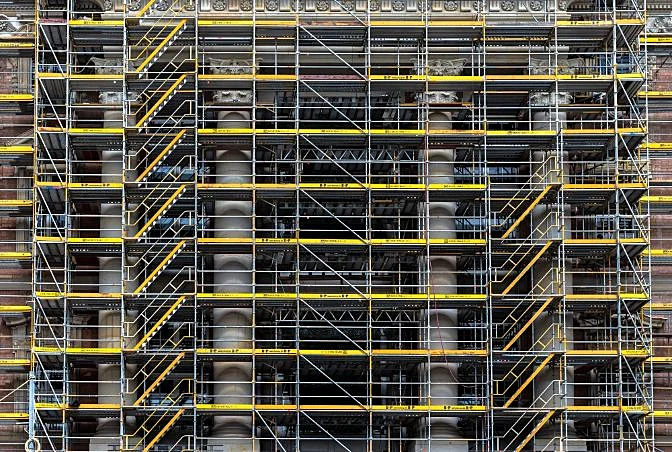

The Importance of Steel Formwork in Modern Construction

In the ever-evolving landscape of construction, efficient and sustainable building practices have become paramount. One of the pivotal elements in achieving such efficiency is the use of steel formwork. Steel formwork refers to the temporary or permanent molds used to hold concrete in place during the curing process. This method has gained significant traction in the construction industry due to its numerous advantages over traditional wooden formwork.

Steel formwork is renowned for its durability and strength. Unlike wood, which can warp or degrade over time, steel maintains its shape and integrity throughout multiple construction cycles. This durability translates into a longer lifespan for the formwork, which can be reused for numerous projects without significant wear and tear. As a result, construction companies that invest in steel formwork can significantly reduce their costs over time, making it a financially sound decision.

The Importance of Steel Formwork in Modern Construction

The use of steel formwork also contributes to a safer work environment. Steel forms are typically heavier than wooden alternatives, which means they can withstand the rigors of construction without the risk of collapse or failure. Additionally, the installation process for steel formwork can be faster and less labor-intensive, reducing the chances of accidents on site. Workers can focus on pouring and finishing the concrete rather than spending excessive time on formwork assembly and disassembly.

steel formwork factory

An often-overlooked benefit of steel formwork is its positive impact on the environment. As the construction industry faces increasing scrutiny regarding its carbon footprint, many companies are turning to sustainable practices. Steel is a recyclable material, and utilizing steel formwork reduces the demand for timber, thereby conserving forests and minimizing deforestation. Moreover, its durability means that fewer resources are required for replacements, decreasing waste and promoting a more sustainable approach to construction.

The lightweight nature of modern steel formwork systems also enhances their appeal. Innovations in technology have led to the development of modular steel formwork systems that are easy to transport and handle. These systems can be assembled quickly on-site, leading to shorter construction times and the ability to tackle more projects simultaneously. In today’s fast-paced construction environment, the ability to meet tight deadlines is a significant competitive advantage.

Furthermore, steel formwork allows for greater versatility in design. Engineers and architects can create more intricate and complex structures, which may be challenging with traditional formwork methods. The flexibility of steel allows for a broader range of architectural expressions and innovative designs, catering to the growing demand for bespoke structures that stand out in urban landscapes.

In conclusion, steel formwork represents a significant advancement in construction techniques. Its durability, precision, safety, environmental benefits, and versatility make it an indispensable tool for modern builders. As the industry continues to embrace innovation and sustainable practices, the use of steel formwork is likely to become even more prevalent. Emphasizing these advantages can help construction companies not only improve their efficiency but also contribute positively to the environment and society. It’s clear that steel formwork is not just a passing trend but a crucial component of the future of construction.

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025

-

China Single Sided Wall Formwork: Fast, Flexible Solutions

NewsAug.14,2025