Dec . 12, 2024 10:11 Back to list

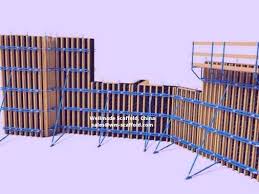

wood formwork concrete suppliers

The Importance of Wood Formwork in Concrete Construction A Look at Suppliers

In the realm of construction, the foundational elements of a building are paramount. Among these, concrete plays a critical role due to its strength and durability. However, to shape and mold concrete into the desired form, contractors rely heavily on formwork. One of the most commonly used materials for formwork is wood. This article explores the significance of wood formwork in concrete construction, the advantages it offers, and what to consider when sourcing from suppliers.

Understanding Wood Formwork

Wood formwork is a temporary structure used to contain and shape freshly poured concrete. Traditionally made from plywood, timber, or oriented strand board (OSB), wood formwork is favored due to its versatility and ease of use. It can be crafted on-site or prefabricated in controlled environments, making it adaptable to various construction needs and design specifications.

Advantages of Wood Formwork

1. Cost-Effectiveness Compared to metal or plastic formwork systems, wood formwork is often more affordable. This lower initial investment can make a significant difference, especially in budget-sensitive projects.

2. Simplicity and Flexibility Wood formwork is straightforward to work with, allowing for quick adjustments and repairs on-site. Its lightweight nature contributes to its ease of handling, making it a popular choice for contractors who prioritize efficiency.

3. Sustainability As a naturally sourced material, wood is renewable and biodegradable. Many suppliers are now focused on sustainable forestry practices, meaning projects using wood formwork can have a smaller environmental footprint.

5. Customization Wood can be easily cut and shaped to meet specific project requirements. This level of customization enables contractors to create unique designs and complex geometries that might be challenging with other materials.

wood formwork concrete suppliers

Sourcing Wood Formwork

When considering wood formwork suppliers, there are several factors to consider to ensure your project’s success

1. Quality of Material It is essential to source high-quality wood that is free from defects such as knots, warping, or decay. The integrity of the formwork directly affects the quality of the finished concrete.

2. Supplier Reputation Choosing a supplier with a strong reputation in the construction community is crucial. Look for reviews, past projects, and testimonials to gauge their reliability and service quality.

3. Sustainability Practices Assess whether the supplier adheres to environmentally friendly practices. Many construction companies today prioritize sustainable materials, and partnering with a supplier who shares this value can enhance your project's eco-friendliness.

4. Delivery and Availability Timely delivery of formwork materials is critical in construction. Ensure that your chosen supplier can meet your project’s timeline and has sufficient inventory to avoid delays.

5. Technical Support and Advice Good suppliers often provide technical support and guidance regarding the use of their products. This assistance can be invaluable, especially for complex projects or if you’re using wood formwork for the first time.

Conclusion

Wood formwork remains a vital aspect of concrete construction. Its cost-effectiveness, versatility, and aesthetic benefits make it a preferred choice among contractors. By carefully selecting a reputable supplier, builders can ensure that they receive high-quality materials that contribute to the success of their projects. As the construction industry continues to evolve, the enduring benefits of wood formwork will likely maintain its popularity for years to come.

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025