Oct . 05, 2024 21:25 Back to list

oem round formwork

The Importance of OEM Round Formwork in Modern Construction

In the ever-evolving landscape of construction, efficiency and innovation are paramount. One solution that has gaining traction in recent years is the use of OEM (Original Equipment Manufacturer) round formwork. This specialized type of formwork offers a plethora of advantages for various construction projects, particularly in creating curved structures, enhancing construction efficiency, and ensuring optimal safety standards on site.

Understanding OEM Round Formwork

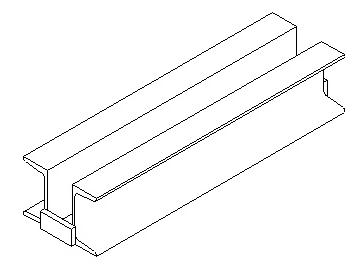

OEM round formwork is manufactured by specialized companies that create custom formwork solutions tailored to the specific needs of a project. This process involves the design, fabrication, and supply of formwork systems that are engineered to meet intricate specifications, allowing for the construction of rounded or curved concrete structures. Common applications include water tanks, arches, silos, and other circular structures that demand precision and reliability.

Advantages of OEM Round Formwork

1. Customization One of the most significant benefits of OEM round formwork is its ability to be customized. Each project has unique requirements regarding dimensions, curvature, and load-bearing capacity, and OEM manufacturers can tailor their products accordingly. This level of customization ensures that the formwork fits perfectly, reducing the likelihood of issues during the pouring process.

2. Efficiency Time is money in the construction industry, and OEM round formwork can significantly enhance the efficiency of the building process. Prefabricated formwork systems can be quickly assembled on-site, allowing contractors to reduce labor costs and project timelines. Additionally, their reusable nature means that they can be used for multiple projects, further improving cost-effectiveness.

3. High Quality and Durability OEM manufacturers often use high-quality materials designed to withstand the pressures of concrete pouring and curing. This durability ensures that the formwork can be reused for various projects, thereby maximizing return on investment. Furthermore, these formwork systems are engineered to provide a smooth finish, which can minimize the need for additional finishing work once the concrete has set.

oem round formwork

4. Safety Safety is a critical concern in any construction project. OEM round formwork is designed with safety features that protect both workers and the integrity of the structure. The robust construction and secure assembly methods help prevent accidents during the pouring and curing processes. Additionally, their precise engineering reduces the risk of structural failures, promoting a safer workplace.

5. Environmental Impact In today’s world, sustainability is key. OEM round formwork often incorporates environmentally friendly materials and practices in their manufacturing process. The ability to reuse formwork multiple times not only conserves resources but also reduces waste significantly, making it a more eco-friendly option in construction projects.

Applications of OEM Round Formwork

The versatility of OEM round formwork allows it to be used in numerous applications within the construction industry. It is particularly advantageous in projects that require the construction of structures with complex geometries. For instance, bridges, stadiums, and aesthetic architectural features often benefit from the use of round formwork. Additionally, in civil engineering, structures such as tunnels and water treatment facilities are prime candidates for OEM round formwork solutions.

Conclusion

As the construction industry continues to seek innovative and efficient solutions, OEM round formwork stands out as a formidable option. Its benefits, including customization, efficiency, high quality, safety, and environmental sustainability, make it a preferred choice for many construction projects requiring curved or rounded concrete structures. By leveraging the advantages of OEM round formwork, construction professionals can not only enhance the efficiency of their projects but also contribute to safer and more sustainable building practices.

In a world where precision and effectiveness are essential, the significance of OEM round formwork cannot be overstated. Its implementation can lead to high-quality results and contribute to the architectural beauty and integrity of modern infrastructure. As the industry progresses, embracing such advanced solutions will be critical in meeting the challenges of tomorrow’s construction landscape.

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025