Ago . 08, 2024 15:25 Back to list

Concrete Beam Bridge Deck Formwork Solutions for Efficient Construction and Durability in Infrastructure Projects

Concrete Beam Bridge Deck Formwork Factory An Essential Component in Bridge Construction

In the realm of civil engineering and construction, the significance of specialized factories cannot be overstated. Among these, a concrete beam bridge deck formwork factory holds a pivotal role in ensuring the efficiency, safety, and quality of bridge construction projects. This article delves into the functions, importance, and innovation within such factories, highlighting their contribution to modern infrastructure development.

Understanding Formwork

Formwork is a temporary or permanent mold into which concrete is poured to achieve desired shapes and dimensions. Specifically, concrete beam bridge decks require precise formwork to accommodate the unique design and load-bearing specifications of the structure. The quality of formwork not only influences the construction timeline and cost but also the overall stability and durability of the bridge.

The Function of a Concrete Beam Bridge Deck Formwork Factory

A concrete beam bridge deck formwork factory specializes in designing, manufacturing, and supplying formwork systems tailored specifically for bridge deck applications. These systems can include reusable modular formwork, stay-in-place forms, and custom-designed solutions. The factory's operations typically encompass

1. Design and Engineering Skilled engineers and designers collaborate to create innovative formwork solutions that meet industry standards and the specific requirements of each bridge project. This phase involves careful calculations and simulations to ensure that the formwork can withstand the stresses of pouring and curing concrete.

2. Manufacturing Once the designs are finalized, the production process begins. High-quality materials, such as steel, aluminum, and plywood, are sourced to construct durable and robust formwork systems. Advanced manufacturing techniques, including precision cutting, welding, and assembly, are employed to ensure accuracy and reliability.

concrete beam bridge deck formwork factory

3. Quality Control Rigorous quality control measures are implemented throughout the manufacturing process. Each formwork piece is inspected for defects and tested for strength and durability. This attention to detail is crucial for maintaining safety standards and ensuring the structural integrity of the final product.

4. Logistics and Distribution Once manufactured, the formwork systems are prepared for delivery to construction sites. Efficiency in logistics is vital, as timely delivery can significantly impact project schedules. Factories often have arrangements for transporting large and heavy formwork pieces, ensuring they arrive in optimal condition.

The Importance of Innovation in Formwork Design

The construction industry is continually evolving, with increasing pressures to improve efficiency and reduce costs. As a result, concrete beam bridge deck formwork factories are embracing new technologies and methodologies. Innovations such as prefabricated formwork systems, 3D printing, and the use of lightweight materials are becoming more prevalent. These advancements not only streamline the construction process but also enhance the performance and versatility of formwork solutions.

Sustainability is another key focus area. Factories are increasingly adopting eco-friendly practices and materials. This includes using recycled materials in formwork production and implementing energy-efficient manufacturing processes. Such initiatives align with global trends towards greener construction practices and demonstrate a commitment to environmental responsibility.

Conclusion

In summary, a concrete beam bridge deck formwork factory is a critical player in the bridge construction landscape. Through innovative design, robust manufacturing, stringent quality control, and a commitment to sustainability, these factories provide essential support to engineers and contractors alike. As infrastructure development continues to advance, the role of formwork factories will undoubtedly evolve, continuing to contribute significantly to the quality and safety of bridges around the world.

-

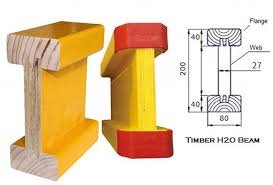

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025