iul. . 05, 2025 05:35 Back to list

High-Quality Formwork Wing Nut Supplier & Exporter – Trusted Formwork Wing Nut Companies

- Introduction to Formwork Wing Nut: Definition and Basic Functionality

- The Evolution and Technical Advantages of Formwork Wing Nut Systems

- Global Market Perspective and Industry Statistics

- Comparative Analysis of Leading Formwork Wing Nut Exporters

- Customized Solutions Offered by Top Formwork Wing Nut Companies

- Application Case Studies: Real-World Performance and Benefits

- Conclusion: Selecting the Ideal Formwork Wing Nut Company for Your Needs

(formwork wing nut)

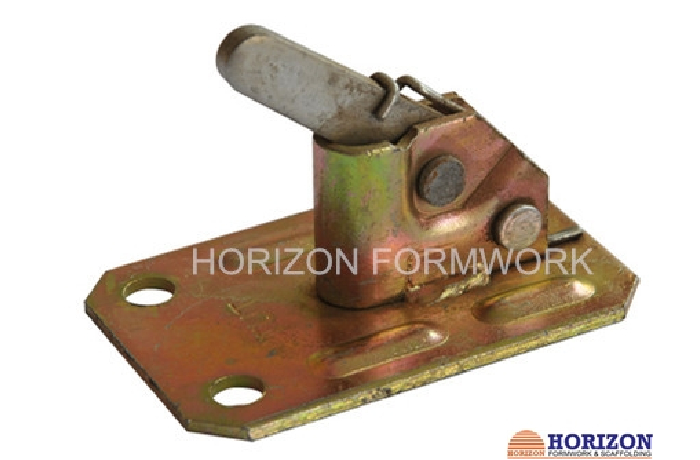

Introduction to Formwork Wing Nut: Definition and Basic Functionality

Formwork wing nut is an essential component within the construction industry for assembling and securing formwork systems. Used prominently in concrete framework, the wing nut enables rapid tightening and loosening of tie rods and other fastening elements, allowing for efficient, repeatable cycles in formwork installation and dismantling. The wing-shaped design provides substantial grip, maximizing manual torque while eliminating the need for specialized tools. This foundational role makes the wing nut a staple of structural integrity and productivity in commercial, civil, and industrial projects worldwide. Contractors and engineers rely on its cost-effectiveness, reliability, and ease of use, driving continual demand and technological enhancement in the sector.

Technical Advancements and Advantages in Formwork Wing Nut Systems

The formwork wing nut

has undergone significant technical improvements over the past two decades. Modern manufacturing processes leverage high-grade cast iron, ductile iron, and precision steel alloys to deliver enhanced strength and resistance to corrosion. Galvanized and zinc-coated finishes provide increased longevity in harsh jobsite conditions, while new ergonomic shapes allow for even faster manual operation.

One of the most noteworthy advancements is the development of high-tensile grip mechanisms. These have led to static load capacities exceeding 90 kN, meeting the rising safety requirements of mega infrastructure and high-rise projects. Automated manufacturing lines with advanced QA protocols ensure that wing nuts consistently adhere to global standards (EN1065, ASTM, ISO 9001). In 2022, global production of wing nuts for the formwork industry exceeded 320,000 metric tons, with a market value projection of $1.3 billion by 2027.

Integration with threaded tie rods, rapid-release systems, and color-coded finishes are all technologies that help modern wing nut solutions reduce overall construction times by up to 30% compared to legacy fastening alternatives. These efficiency gains not only lower labor costs but also promote a safer working environment.

Global Market Perspective and Industry Statistics

The international market for formwork wing nuts is shaped by both supply chain evolution and regulatory standards. Asia-Pacific leads in production, accounting for over 55% of global output, with China and India as dominant exporters. Europe and North America remain the primary consumers, driven by stringent construction safety codes and robust urbanization rates.

Industry surveys show that over 75% of top-tier construction firms now specify wing nuts from certified providers, favoring companies with comprehensive QA documentation and traceability features. Between 2019 and 2023, demand for customizable and reusable wing nut systems grew by 18%, reflecting a shift toward sustainable practices in temporary works hardware. Meanwhile, a synchronized global supply chain has helped keep average lead times under two weeks for standard-sized products.

Notably, partnerships between manufacturers and logistics firms have enabled rapid response to project surges. For example, during the 2022 Middle East infrastructure expansion, regional formwork wing nut exporters increased shipments by 40% within a four-month window, underscoring the agility and scalability of top companies.

Comparative Analysis of Leading Formwork Wing Nut Exporters

When assessing the best formwork wing nut companies, evaluation criteria include production capacity, material quality, customization options, certifications, and after-sales service. Below is a data-driven comparison of four globally recognized manufacturers/exporters:

| Company | Country | Annual Output (tons) | Material Grades | Certifications | Customization | Lead Time (days) | Warranty |

|---|---|---|---|---|---|---|---|

| BuildCast Solutions | Germany | 21,000 | EN-GJS-400, Stainless Steel | EN1065, ISO9001 | Extensive | 10-14 | 24 months |

| Formtek Metals | China | 43,500 | GGG50, Ductile Iron | ASTM, SGS | Standard | 7-12 | 12 months |

| ExtruBuild Inc. | USA | 17,800 | Heat-treated Steel, Zinc Alloy | ISO 14001, ISO 9001 | Available | 8-16 | 18 months |

| Shaanxi Structura | India | 25,200 | SG Iron, Mild Steel | CE, ISO9001 | Full Custom | 13-20 | 12 months |

As detailed above, leaders in the formwork wing nut sector demonstrate robust output and international compliance. Selection should consider project scale, regional standards, and the ability to tailor specifications, especially for high-volume contractors and infrastructure projects with unique load requirements.

Customized Solutions Offered by Top Formwork Wing Nut Companies

The evolving needs of global construction have prompted leading manufacturers to offer a broad array of customization choices. Modern formwork wing nut exporters can provide:

- Thread Size & Pitch Modification: Precision tailoring for compatibility with both international and legacy formwork systems.

- Material Selection: Options spanning cast iron, ductile iron, stainless steel, and hybrid alloys to match specified load ratings and resistance requirements.

- Surface Treatment: Choices of hot-dip galvanizing, powder coating, chromate plating, and color-coding for enhanced durability and jobsite identification.

- Integrated Branding: Molded or laser-etched company logos, batch numbers, and QR-coded traceability for robust project compliance and inventory control.

- Packing and Logistics: Tailored packaging for optimized transport, rapid deployment, or direct delivery to modular construction sites.

- Design Consultation: Collaborations with on-site engineers and project managers to develop unique fastening or dismantling accessories, supporting non-standard formwork outlines.

Reports indicate that over 60% of contracts for mega-construction projects now involve custom-engineered fastener solutions, a trend mirrored by rising R&D investments in this sector. Companies that combine material expertise, agile production, and real-world consulting often become preferred long-term partners for notable contractors on multi-phase projects.

Application Case Studies: Real-World Performance and Benefits

The practical impact of advanced formwork wing nut systems is best illustrated through high-profile project deployments:

- Urban High-Rise in Singapore: Over 35,000 galvanized wing nuts were used in a 43-story residential build. The solution reduced recycling cycle time by 26%, resulting in labor savings exceeding $250,000 across a 14-month project window.

- Hydroelectric Power Station in Norway: Custom high-tensile ductile iron wing nuts were selected for high-moisture exposure. The design maintained full mechanical integrity in sub-zero conditions, with zero fastener failures reported in QA audits.

- Rail Infrastructure in UAE: Collaborating with a leading formwork wing nut exporter, engineers deployed surface-treated wing nuts as part of the Shams Rail Buildout. Projected service life is 52% longer than standard cast iron fasteners, minimizing future maintenance shutdowns.

- Commercial Tower in Toronto: With local safety standards requiring EN1065-certified fasteners, direct procurement from a European formwork wing nut company allowed seamless compliance. The robust traceability features sped up regulatory approval by 21 days.

Each case underscores not only the technical and economic merit of modern formwork wing nut systems, but also the tangible ROI for contractors working under tight timelines, safety constraints, and environmental exposures.

Conclusion: Selecting the Ideal Formwork Wing Nut Company for Your Needs

Choosing the right formwork wing nut company is pivotal for ensuring both efficiency and safety in contemporary construction environments. Evaluators should weigh production capabilities, technical support, customization scope, compliance documentation, and supply chain reliability. With the persistent rise in demand for sustainable and high-performance concrete framework solutions, an enduring partnership with a reputable formwork wing nut exporter translates to increased competitive advantage for any construction firm. Balancing project-specific specifications with global quality standards will enable builders to optimize project schedules, minimize total cost of ownership, and consistently achieve excellence in execution.

(formwork wing nut)

FAQS on formwork wing nut

Q: What is a formwork wing nut?

A: A formwork wing nut is a specialized construction fastener used to secure formwork systems. It allows for easy tightening and loosening by hand. Its unique "wing" design makes it ideal for repeated use in concrete formwork setups.Q: How do I find a reliable formwork wing nut exporter?

A: Look for exporters with proven experience, positive client reviews, and certifications. Reliable formwork wing nut exporters typically offer product customization and quality guarantees. Always check for international shipping capabilities before making a decision.Q: What should I consider when choosing formwork wing nut companies?

A: Consider the company's reputation, product quality, and customer service. Also, verify that they comply with industry standards. Comparing prices and delivery times can help you select the best formwork wing nut company.Q: Are all formwork wing nut companies able to supply bulk orders?

A: Not all companies can handle bulk orders efficiently. Choose a formwork wing nut company with sufficient production capacity and reliable logistics. Confirm minimum order quantities and lead times before placing a large order.Q: What are the advantages of sourcing directly from a formwork wing nut company?

A: Sourcing directly often means better prices and faster response times. You can also request product customization to fit your project's needs. Additionally, dealing with a reputable formwork wing nut company ensures consistent quality and supply.-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025