aug. . 13, 2024 02:58 Back to list

Innovative Solutions for Efficient Formwork Systems in Concrete Slab Manufacturing Facilities

Formwork for Concrete Slab Factories Essential Techniques and Considerations

In the construction industry, formwork is a crucial component for creating concrete structures, especially for concrete slabs in factories. Formwork refers to the temporary or permanent molds used to shape concrete until it hardens. Understanding the various aspects of formwork not only enhances the quality and efficiency of construction but also ensures safety and sustainability in the manufacturing process.

Types of Formwork

There are several types of formwork used in concrete slab construction, each with its own advantages and applications. The most common types include

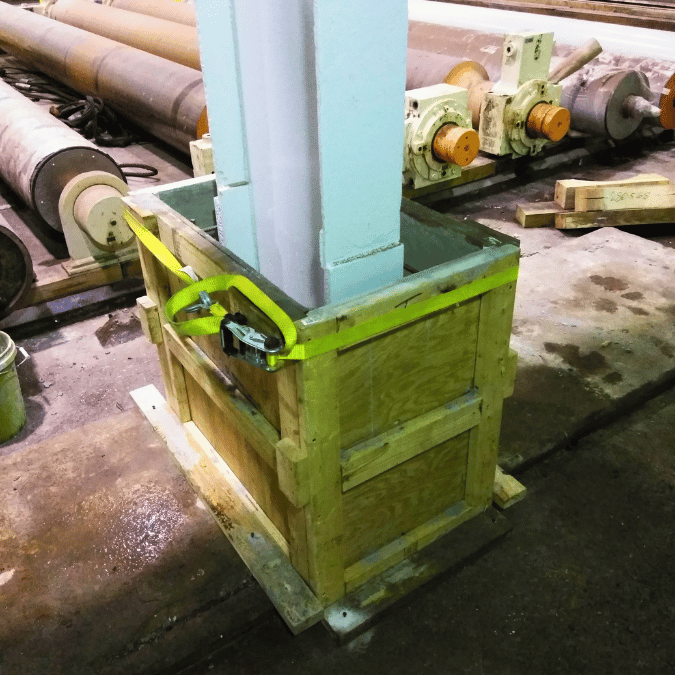

1. Traditional Timber Formwork This is the classic method, utilizing wood planks to create molds. Timber formwork is versatile and can be customized to fit unique designs. However, it requires skilled labor for assembly and disassembly, and it may not be as durable as other options.

2. Plywood Formwork Plywood is often used in conjunction with timber to create strong and sturdy forms. It offers a smoother finish compared to raw timber and is less prone to warping. Plywood formwork is applicable for both small and large projects, making it a popular choice among contractors.

3. Steel Formwork Steel forms are reusable and more durable than wood-based alternatives. They provide excellent dimensional accuracy and a smooth finish, which can reduce the need for additional finishing work on the concrete slab. While the initial investment is higher, the long-term savings associated with reusability make steel formwork a cost-effective option for large-scale projects.

4. Plastic Formwork Light-weight and easy to assemble, plastic formwork is ideal for small projects or specific applications where portability is essential. Although less durable compared to steel, plastic forms can be a viable option for projects with tight budgets.

Key Considerations for Formwork Design

formwork for concrete slab factories

When selecting and designing formwork for concrete slab factories, several factors must be taken into account

1. Load-Bearing Capacity The formwork must support the weight of the wet concrete as well as any additional loads during the curing process. It is crucial to assess the load-bearing requirements to prevent structural failures.

2. Time Efficiency Speed of assembly and disassembly is vital in factory settings, where time translates to cost. Selecting materials and methods that allow for quick setup will enhance overall project efficiency.

3. Surface Finish The quality of the surface finish on concrete slabs can significantly impact downstream processes such as painting or flooring installation. Choosing the right formwork material can enhance aesthetic qualities and minimize post-pour repairs.

4. Cost-Effectiveness While upfront costs are a consideration, evaluating long-term savings through reusability and reduced labor is vital. Factories must strike a balance between quality and affordability to ensure profitability.

5. Environmental Impact Sustainable construction practices are increasingly important in modern industries. Utilizing materials that have a lower ecological footprint or can be recycled after their use is essential for companies looking to reduce their impact on the environment.

Conclusion

The selection and implementation of formwork for concrete slab factories is a fundamental aspect of construction that can influence the quality, efficiency, and sustainability of the final product. By understanding the types of formwork available, the key considerations in their design, and the importance of proper execution, construction professionals can enhance their operations, ensuring that projects are completed successfully and in a timely manner. As the demand for innovative construction solutions continues to grow, staying informed about advancements in formwork technology will be paramount for continued success in the industry.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025