dec. . 31, 2024 09:28 Back to list

tunel formwork manufacturer

The Evolution and Significance of Tunnel Formwork Manufacturers in Modern Construction

In the contemporary landscape of construction, efficiency and speed are paramount. As the need for rapid urbanization and infrastructure development increases, the spotlight has shifted towards innovative construction methods. One such technique that has gained immense traction is the use of tunnel formwork systems, revolutionized by specialized manufacturers. These manufacturers play a crucial role in ensuring that construction projects meet both the demanding schedules and the quality standards of modern engineering.

Understanding Tunnel Formwork

Tunnel formwork is a method used for the construction of concrete structures, particularly multi-story buildings. This system utilizes large, pre-constructed forms in the shape of a tunnel, effectively allowing concrete to be poured into predetermined sections of a building. The unique design enables simultaneous construction of walls and ceilings, significantly reducing labor time and increasing productivity. The adaptability of tunnel formwork makes it suitable for a variety of projects ranging from residential buildings to commercial structures and even infrastructure works.

Benefits of Tunnel Formwork

The advantages of employing tunnel formwork systems are manifold. First and foremost is the speed of construction. Typically, structures using tunnel formwork can be erected in a fraction of the time compared to traditional methods. A construction team can complete a single floor in as little as one to two days, enabling rapid project turnover.

Secondly, tunnel formwork promotes high-quality finishes. The homogeneous nature of the cast-in-place concrete created by the system leads to superior structural integrity and durability. The consistent wall thickness and surface finish ensure that the final product meets rigorous industry standards. Additionally, the reduction of joints minimizes the potential for water ingress and structural weaknesses.

Moreover, tunnel formwork systems contribute significantly to cost savings. The efficiency of the system reduces labor costs and the time involved in formwork setup and removal. Also, the repetitive nature of the formwork usage maximizes its lifespan, providing excellent value to construction companies. When tunnel formwork is managed correctly, it can also reduce material waste, contributing to more sustainable building practices.

tunel formwork manufacturer

The Role of Tunnel Formwork Manufacturers

Tunnel formwork manufacturers form the backbone of this innovative construction method. They are responsible for the design, production, and delivery of these complex systems. Leading manufacturers are investing in advanced technologies, including computer-aided design (CAD) and simulation software, to create more efficient and customizable formwork solutions.

These manufacturers also play a pivotal role in educating construction firms about the best practices for using tunnel formwork systems. Through training and support, they help ensure that their clients are equipped to maximize the benefits of this technology while minimizing potential challenges.

Furthermore, as the construction sector increasingly emphasizes sustainability, manufacturers are striving to innovate and produce eco-friendly formwork solutions. The integration of recyclable materials and the development of energy-efficient manufacturing processes demonstrate the industry’s commitment to environmental stewardship.

Future Trends in Tunnel Formwork

As the industry evolves, tunnel formwork manufacturers will continue to adapt to new challenges and opportunities. The rise of prefabricated construction elements and smart building technologies presents exciting prospects for further enhancing the efficiency and capabilities of tunnel formwork systems.

In conclusion, tunnel formwork manufacturers are vital players in the construction industry, enabling the rapid, cost-effective, and high-quality construction of a range of structures. Their ongoing innovations and commitment to excellence will undoubtedly shape the future of construction, paving the way for more efficient building practices. As urban populations grow and the demand for infrastructure escalates, tunnel formwork will remain an essential component of the modern construction landscape.

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

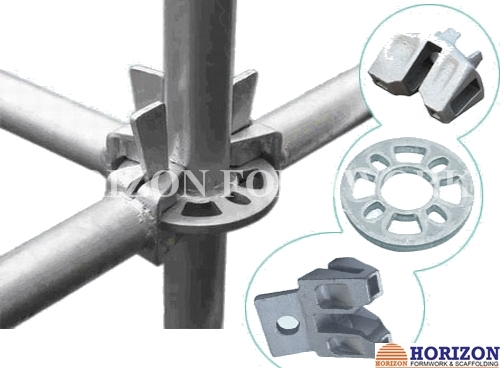

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025