Nov . 24, 2024 02:17 Back to list

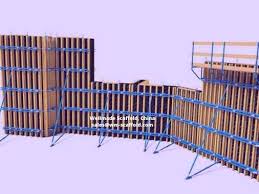

scaffolding for slab formwork factories

Scaffolding for Slab Formwork Factories A Comprehensive Overview

Scaffolding plays a crucial role in the construction industry, especially when it comes to slab formwork factories. These structures are vital for providing support during the placement of concrete slabs in various projects, including residential buildings, commercial complexes, and industrial facilities. This article will explore the importance of scaffolding in slab formwork operations, the types of scaffolding used, and best practices for ensuring safety and efficiency on the job site.

Importance of Scaffolding in Slab Formwork

In slab formwork, scaffolding serves as a temporary structure that supports the formwork systems and helps shape the concrete until it sets. The significance of scaffolding cannot be overstated, as it enables construction workers to access elevated work areas safely and securely. Additionally, scaffolding contributes to the overall efficiency of the slab pouring process by providing stable platforms for workers to operate from.

Moreover, proper scaffolding ensures that the formwork remains in place until the concrete cures, reducing the risk of structural failure. Safety is a paramount concern in any construction environment, and inadequate scaffolding can lead to accidents, injuries, and costly project delays. Therefore, utilizing the right scaffolding solutions is fundamental for seamless slab formwork operations.

Types of Scaffolding Used

There are several types of scaffolding that can be employed in slab formwork, each with its unique features and benefits

1. Ringlock Scaffolding This modular system consists of standardized components that can be easily assembled and disassembled. It is known for its robustness and versatility, making it suitable for various heights and load capacities associated with slab formwork.

2. Cuplock Scaffolding This type features a unique fastening system that allows for quick assembly and disassembly. Its efficiency and stability make it an excellent choice for supporting formwork systems during concrete pouring.

3. Frame Scaffolding Often used in lower-height applications, frame scaffolding provides a straightforward and economical solution for accessing work areas. It is commonly used for smaller slab formwork projects or in instances where height is not a significant concern.

scaffolding for slab formwork factories

4. Shoring Systems In slab formwork, shoring provides temporary support to the structural elements during construction. Shoring systems can vary from adjustable props to more complex arrangements that accommodate unique project requirements.

Best Practices for Scaffold Safety and Efficiency

To maximize the effectiveness of scaffolding in slab formwork, it is essential to adhere to several best practices

1. Regular Inspections Before each use, scaffolding should undergo thorough inspections to identify any damage or instability. Regular maintenance helps ensure safety and reduces the risk of accidents.

2. Proper Training Workers should receive adequate training on scaffolding setup, load capacities, and safety protocols. Understanding how to properly use scaffolding is vital for reducing hazards on the job site.

3. Load Management Each type of scaffolding has specific load capacity limits. It is crucial to adhere to these limits to prevent collapse or structural failure.

4. Weather Considerations Weather conditions can impact the stability of scaffolding. It is essential to monitor conditions such as wind speed and precipitation levels, making adjustments as necessary for optimal safety.

5. Safety Gear Workers should wear appropriate personal protective equipment (PPE) at all times when working on or around scaffolding. This includes helmets, harnesses, and non-slip footwear to mitigate risks.

Conclusion

Scaffolding is an indispensable element in the realm of slab formwork factories. Its role in providing support, safety, and accessibility cannot be overlooked. By understanding the various types of scaffolding available and implementing best practices for safety and efficiency, construction projects can proceed smoothly and effectively. Prioritizing scaffolding integrity not only enhances worker safety but also contributes to the overall success of construction endeavors. Ultimately, investing in proper scaffolding solutions pays dividends in the form of enhanced productivity, safety, and quality in slab formwork operations.

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025