Nov . 30, 2024 03:18 Back to list

formwork for concrete structures manufacturer

Formwork for Concrete Structures An Essential Component in Construction

In the realm of construction, the term formwork refers to the temporary or permanent molds that shape concrete into the desired form of a structure. A crucial element for any concrete construction project, formwork plays a vital role in ensuring structural integrity, efficiency, and safety. This article delves into the various types of formwork, the importance of selecting the right manufacturer, and the evolving technologies that are shaping the future of concrete construction.

Understanding Formwork Types

Formwork can be categorized into several types, each serving specific purposes and applications. The most common types include

1. Timber Formwork Traditionally used in construction, timber formwork is highly versatile and can be easily constructed on-site. It's cost-effective for small-scale projects but may not be suitable for large or complex structures due to potential deformation and variability in wood quality.

2. Steel Formwork Known for its durability and reusability, steel formwork is ideal for large-scale construction projects. It can withstand the pressure of wet concrete and is less likely to deform compared to timber. However, it is heavier and may require more precision in manufacturing and installation.

3. Aluminum Formwork Lightweight and modular, aluminum formwork is gaining popularity for its quick assembly and disassembly. This type of formwork is particularly beneficial for high-rise buildings, where efficiency is crucial.

4. Plastic Formwork An innovative solution, plastic formwork offers flexibility and ease of handling. It's resistant to chemical damage and is often used in residential projects. However, the lifespan of plastic formwork may be shorter than that of steel or aluminum.

5. Permanently Integrated Formwork This type of formwork becomes an integral part of the structure, providing thermal insulation and soundproofing. It's often used in precast concrete systems.

The Importance of Choosing the Right Manufacturer

Selecting a reliable formwork manufacturer is paramount for the success of any concrete project. A reputable manufacturer will provide high-quality materials that comply with industry standards, ensuring the safety and durability of the final structure. Several factors to consider when choosing a manufacturer include

formwork for concrete structures manufacturer

- Experience and Reputation Established manufacturers tend to have a proven track record and can provide references or case studies demonstrating their work's quality.

- Customization Options A good manufacturer should be able to customize formwork solutions based on the specific needs of the project. This is particularly important for complex architectural designs.

- Customer Support Choosing a manufacturer that offers excellent customer service, including installation guidance and after-sales support, can significantly impact the overall project timeline and success.

- Sustainability Practices As the construction industry moves towards more sustainable practices, selecting a manufacturer that focuses on environmentally friendly materials and processes is becoming increasingly important.

Innovations in Formwork Technology

The construction industry is continuously evolving, with advancements in formwork technology leading to increased efficiency and reduced costs. Some notable trends include

- 3D Printing Innovations in 3D printing technology allow for the creation of bespoke formwork solutions that can be tailored to specific project requirements. This technology promises to cut down production time and material waste.

- Digital Modeling Using Building Information Modeling (BIM), contractors can plan and simulate the formwork process digitally, which helps in identifying potential issues before the actual construction begins.

- Smart Formwork Systems Integrating technology into formwork systems can improve monitoring and quality control during the concrete curing process. Sensors can be used to track temperature and humidity, ensuring optimal conditions for concrete setting.

Conclusion

Formwork is an indispensable element of concrete construction, influencing the quality, safety, and efficiency of structural projects. By understanding the various types of formwork, choosing a reputable manufacturer, and embracing technological innovations, construction professionals can enhance their project outcomes. The future of concrete construction is bright, driven by advancements that promise to make processes safer, faster, and more efficient.

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

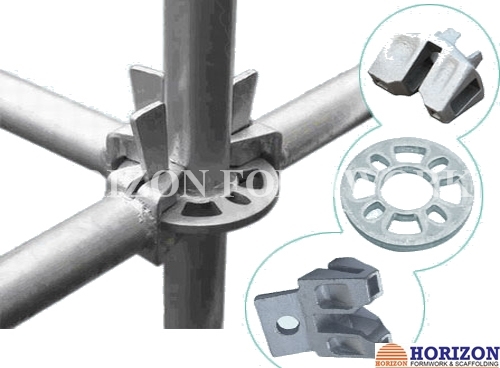

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025