Nov . 08, 2024 17:38 Back to list

h20 beam dimensions company

Exploring H2O Beam Dimensions in the Company Context

In the realm of engineering and manufacturing, precise specifications are paramount for quality production and structural integrity. One of the key components that often demand rigorous attention to detail is the beam, particularly the H2O beam dimensions, pertinent in various applications across industries. This article aims to delve into the significance, applications, and specifications of H2O beams within the corporate framework, highlighting their crucial role in modern engineering.

Understanding H2O Beams

H2O beams are specially designed structural elements used predominantly in construction, civil engineering, and architectural frameworks. The term H2O refers to the specific geometric shape of the beam, which resembles the letter H in cross-section, characterized by its strong and stable design. This shape is highly effective in withstanding bending moments and shear forces, making it an ideal choice for supporting heavy loads in various structures, from bridges to skyscrapers.

Importance of Accurate Dimensions

The dimensions of H2O beams are critical for several reasons. Firstly, they determine the load-bearing capacity of the beam, which is essential for ensuring the safety and reliability of structures. Engineers and architects must consider factors such as span length, load distribution, and the nature of materials used when specifying beam dimensions. Any deviation from the precise specifications could lead to structural failures, posing risks to safety and requiring costly repairs or rebuilds.

Moreover, the dimensions of H2O beams can significantly influence the overall design and aesthetics of a building. In contemporary architecture, where innovative designs often challenge traditional forms, the integration of custom beam dimensions allows for creative freedom. This flexibility enables architects to experiment with varying heights, widths, and lengths, tailoring each beam to meet specific design needs while adhering to safety regulations.

Applications Across Industries

h20 beam dimensions company

H2O beams find applications in diverse sectors, reflecting their versatility and efficiency. In the construction industry, they are primarily utilized for framing, providing essential support in residential, commercial, and industrial buildings. Their robust design allows them to handle substantial loads, making them integral to high-rise constructions.

In the transportation sector, H2O beams are commonly employed in bridge construction. The strength and durability of these beams are vital to ensuring that bridges can accommodate traffic loads, withstand environmental stressors, and maintain structural integrity over time. The aerospace industry also leverages H2O beams in fuselage designs, where weight savings and strength are crucial.

Considerations in Manufacturing

Manufacturing H2O beams entails specific processes that ensure they meet the necessary dimensional and structural requirements. Companies engaged in producing these beams must adopt advanced technology and quality control measures. This often includes the use of computer-aided design (CAD) software to create detailed specifications and simulations, ensuring precision in production.

Material selection is another critical consideration. H2O beams can be constructed from various materials, including steel, aluminum, and reinforced concrete. Each material comes with its own set of properties, influencing the final beam's weight, strength, and resistance to environmental factors. Companies must carefully balance these considerations with cost, availability, and the specific needs of their clients.

Conclusion

In summary, the understanding and application of H2O beam dimensions play a pivotal role in engineering and construction. Their importance cannot be overstated, as precise dimensions ensure structural integrity, influence design aesthetics, and facilitate innovative applications across multiple sectors. As industries continue to evolve, the demand for high-quality, precisely manufactured H2O beams will likely increase, driving companies to invest in advanced technologies and rigorous quality control measures to meet the evolving standards of safety and performance. By appreciating the complexities and significance of H2O beams, stakeholders can ensure the longevity and reliability of their structures, contributing to a safer and more innovative built environment.

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

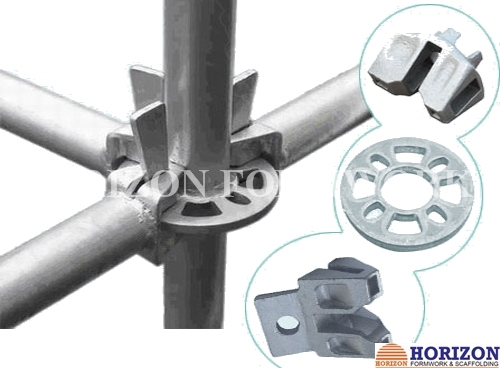

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025