Jul . 27, 2024 04:24 Back to list

High-Quality Steel Formwork Solutions for Construction Projects by Leading Manufacturers in the Industry

The Rise of Steel Formwork Manufacturers in Construction

In the realm of modern construction, the efficiency, safety, and durability of building materials have become paramount. One of the groundbreaking advancements in this domain has been the development of steel formwork systems. Steel formwork manufacturers have emerged as crucial players, offering innovative solutions that significantly enhance the construction process, thereby transforming the industry landscape.

Steel formwork is a vital component used to mold concrete structures during the construction phase. Unlike traditional wooden or plastic formwork, steel formwork is known for its robustness and reusability. This attribute makes it not only cost-effective in the long run but also environmentally friendly due to reduced waste generation from reusable materials.

One of the most significant advantages of using steel formwork is its structural integrity. Steel is known for its strength and durability, which means that it can withstand the immense pressure exerted by wet concrete without warping or collapsing. This characteristic ensures that the concrete sets perfectly, leading to high-quality finishes and consistent results. As a result, construction projects can be completed more efficiently, adhering to tight schedules and reducing labor costs.

Moreover, steel formwork manufacturers have embraced technological advancements to produce lightweight yet sturdy systems. Advances in engineering and manufacturing techniques have led to the development of modular formwork solutions that are easy to assemble and dismantle. This modularity not only speeds up the construction process but also allows for greater flexibility in design and layout, accommodating a variety of architectural requirements.

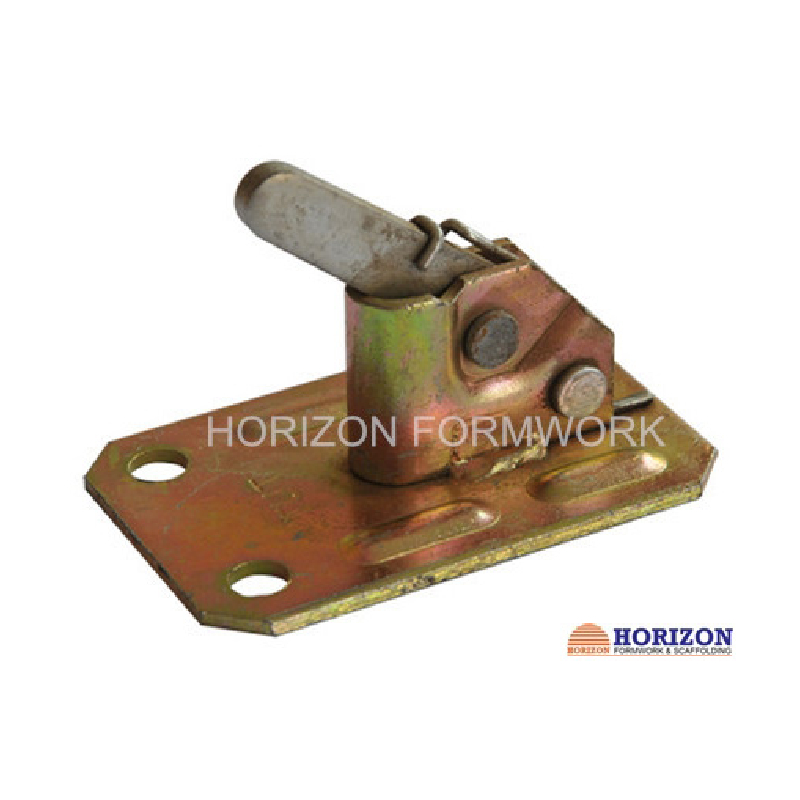

steel formwork manufacturer

In addition to their structural benefits, steel formwork systems exhibit superior longevity compared to their wooden counterparts. While wooden formwork may degrade after a few uses, steel formwork can be reused multiple times, significantly reducing the overall costs for contractors. Furthermore, the lifespan of steel formwork systems often exceeds that of other materials, making them a wise investment for construction companies aiming for sustainability and economic efficiency.

With the growing emphasis on sustainable construction practices, steel formwork manufacturers are also taking steps to minimize their environmental footprint. Many are now producing formwork systems made from recycled steel, further enhancing the eco-friendliness of their products. By using recycled materials, these manufacturers contribute to waste reduction efforts and help in conserving natural resources, aligning with global sustainability goals.

However, the success of steel formwork manufacturers is not solely attributed to the advantages of their products. It also involves their commitment to customer service and innovation. Manufacturers are increasingly investing in research and development to create customized solutions that meet the specific needs of their clients. By providing tailored products and services, they foster long-term partnerships with construction companies and help them tackle unique challenges on different project sites.

Nevertheless, the transition towards steel formwork systems comes with its own set of challenges. Initial investment costs can be higher than traditional formwork options, potentially deterring some companies from making the switch. Education and training on the use of steel formwork are also essential, as the methodology can differ significantly from conventional practices. Manufacturers play a key role in addressing these challenges by providing comprehensive training and support to ensure the successful integration of steel formwork into construction projects.

In conclusion, the role of steel formwork manufacturers is increasingly critical in the construction industry. Their ability to provide durable, efficient, and sustainable formwork solutions not only enhances the building process but also aligns with the industry's evolving demands. As the construction sector continues to grow and innovate, steel formwork manufacturers are poised to remain at the forefront, driving advancements that will define the future of construction.

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025