сеп . 10, 2024 03:45 Back to list

formwork for retaining wall suppliers

Formwork for Retaining Wall Suppliers An Overview

When it comes to constructing durable retaining walls, the choice of formwork is crucial. Formwork serves as a temporary mold that shapes and supports the concrete until it gains sufficient strength. Effective formwork not only ensures the integrity of the retaining wall but also impacts the overall timeline and budget of a project. Therefore, understanding the role of formwork suppliers is essential for both contractors and project managers.

Types of Formwork

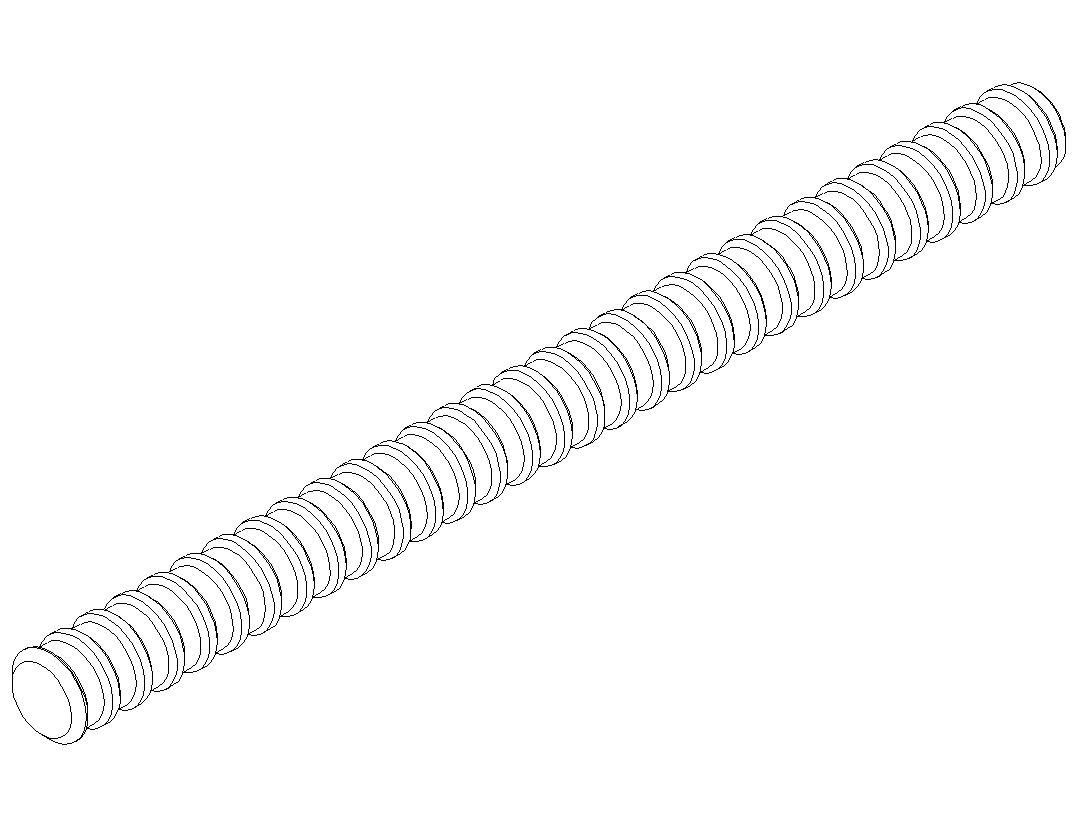

In the industry, several types of formwork are commonly used for retaining walls. These include traditional timber formwork, modular or prefabricated systems, and specialized systems such as lightweight aluminum or steel forms. Timber formwork, while cost-effective and easily available, may be less durable compared to steel or aluminum forms, which can be reused multiple times. Modular systems allow for flexibility in design and can expedite construction, making them increasingly popular among suppliers and builders.

Choosing the Right Supplier

Selecting the best formwork supplier is a critical step in ensuring that a construction project runs smoothly. A reliable supplier should offer not only a wide range of formwork types but also provide essential services such as design assistance, on-site support, and comprehensive training for the installation crew. Suppliers that have experience with retaining walls specifically will be invaluable, as they can offer insights into the best practices and techniques for particular soil and environmental conditions.

Quality and Safety Standards

formwork for retaining wall suppliers

Quality is paramount when it comes to formwork for retaining walls. A good supplier should adhere to stringent safety and quality standards, as the structural integrity of retaining walls is vital for preventing soil erosion and managing water runoff. Formwork that does not meet industry standards can lead to catastrophic failures, which may result in project delays, increased costs, and potential safety hazards. Suppliers should be ready to provide certifications and references to confirm their commitment to quality.

Innovation and Technology

In recent years, the construction industry has witnessed a shift towards more innovative formwork solutions. Suppliers are incorporating advanced technology, such as 3D modeling software for design, to enhance the efficiency of formwork systems. This technological advancement leads to better predictions of material needs and project timelines, ultimately minimizing waste and costs. Suppliers that embrace these innovations can set themselves apart in a competitive market.

Environmental Considerations

With a growing emphasis on sustainability, many formwork suppliers are now offering eco-friendly options. This includes formwork made from recycled materials or designs that minimize waste during the construction process. Choosing a supplier that prioritizes sustainability can benefit the environment and enhance a project’s overall reputation.

Conclusion

In conclusion, formwork suppliers play a significant role in the construction of retaining walls. Their ability to provide high-quality, innovative, and safe formwork solutions contributes to the success of construction projects. Contractors and project managers should prioritize finding suppliers who not only offer a diverse range of formwork options but also emphasize quality, safety, and sustainability. By doing so, they can ensure the longevity and stability of retaining walls while staying on schedule and within budget. Ultimately, the partnership with the right formwork supplier can make all the difference in delivering successful retaining wall projects that stand the test of time.

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025

-

China Single Sided Wall Formwork Manufacturer for Retaining Walls

NewsJul.29,2025

-

High-Quality Scaffolding Jacks for Stable and Safe Support

NewsJul.29,2025