Ho Hloa Foromo ea CB240

Litlhaloso

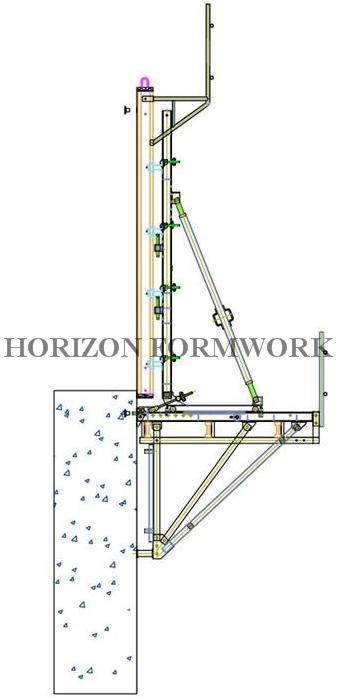

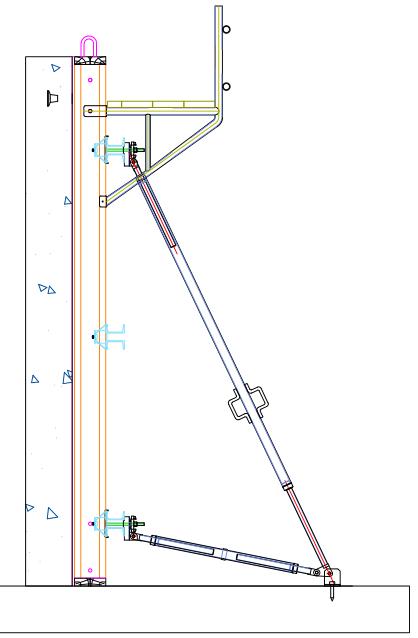

Platform width: 2.4m

Roll-back system: 70 cm with carriage and rack system

Finishing platform: for removing the climbing cone, polishing concrete surface etc.

Anchor system: should be pre-fixed into the formwork and left in the concrete after pouring.

Formwork: can be moved horizontally, vertically and tilted to meet site requirement.

Main platform: provide workers a safe working platform

Finishing platform: there is an access to the main platform by using a safety ladder.

Melemo

- E lumellana le liforomo tsohle tsa lerako la Construccion.

- Li-sete tse entsoeng ka li-brackets le liphanele tsa formwork li fetisetsoa mohatong o latelang oa ho tšela ka lifti ea crane e le 'ngoe.

- E lumellana le meaho efe kapa efe, ho kenyeletsoa mabota a otlolohileng, a sekametseng le a chitja.

- Hoa khoneha ho haha liforomo tsa ho sebetsa maemong a fapaneng.Ho fihlella sethaleng ho fanoang ke litepisi tsa polokeho.

- Li-brackets tsohle li kenyelletsa lihokelo tsohle ho lokisa li-handrails, li-pull-pullprops le lisebelisoa tse ling.

- Li-brackets tsa ho hloa li lumella ho khutlisa sebopeho sa "formwork" ho sebelisa sistimi, e entsoeng ke kariki le rack, e kentsoeng ka har'a mabakete ana.

- Formwork’s vertical adjusting and plumbing is completedwithleveling screw jacks and push-pull props.

- Li-brackets li tšehelitsoe leboteng ka sistimi ea li-ankora.

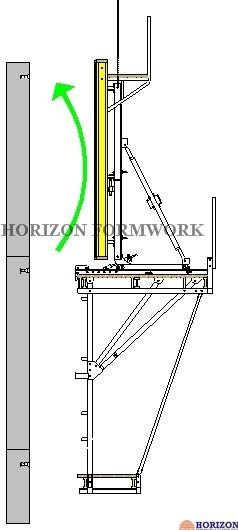

Mokhoa oa ho hloa

|

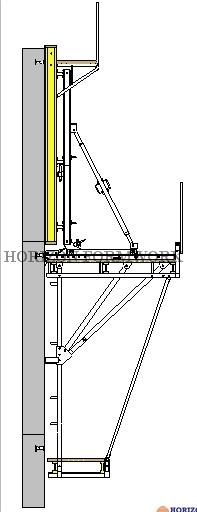

The first pouring is to be completed by using the proper wall elements and has to be exactly e tsamaellanang le dithapo tsa ho lokisa. |

Mohato oa 2 The completely pre-assembled climbing scaffold units consisting of climbing brackets with plank bottom and bracing have to be attached to the bracket anchoring and secured. Then the formwork and the move-off carriage together with the aligning beam has to be positioned on the brackets and fixed. |

|

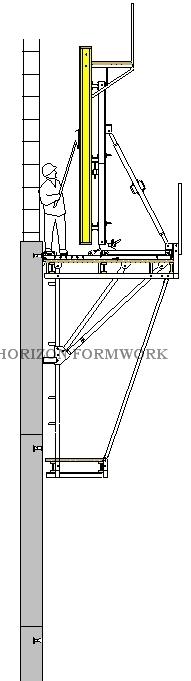

Mohato oa 3 After shifting the climbing scaffold unit to the next pouring position the finishing platform is to be mounted to the brackets to complete the climbing system. |

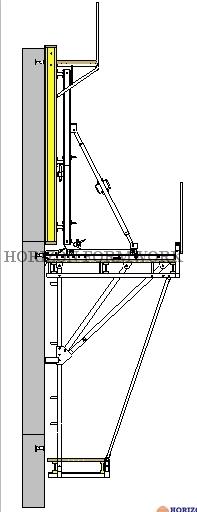

Mohato oa 4 Release and remove bolts that fixing the positioning anchor point. E lokolla 'me u tlose thae-rod Loosen the wedges of the carriage unit. |

|

Mohato oa 5 Retract the carriage and lock it with wedge. Kenya li-cones tse ka holimo Lokolla sesebelisoa sa ho sireletsa moea, haeba se teng Tlosa khoune e tlase ea ho hloa

|

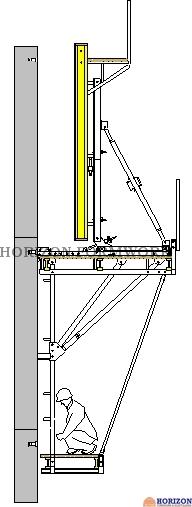

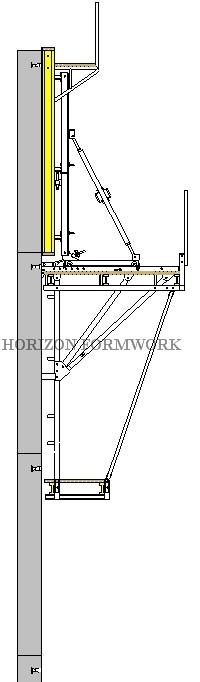

Mohato oa 6 Adjust the carriage into the common center of gravity and lock it again. Hokela letjeketjane la crane ho waling e otlolohileng Tlosa liboutu tsa tšireletso tsa bracket Lift the climbing bracket by crane and attach it to the next prepared climbing cone. Kenya le ho notlela liboutu tsa tšireletso hape. Kenya sesebelisoa sa moea, haeba ho hlokahala. |

|

Mohato oa 7 Move the carriage back and lock it by wedge. Hloekisa foromo. Kenya litšepe tse matlafatsang. |

Mohato 8 Move the formwork forward until lower end rests against top of the finished section of the wall Fetola sebopeho se otlolohileng ka ho sutumelletsa-hula brace. Lokisa thae-rods bakeng sa formwork lebota |

Mohato oa 1

Mohato oa 1