Nov . 12, 2024 10:10 Back to list

china tunnel lining formwork

The Role of Tunnel Lining Formwork in Modern Construction

The construction of tunnels is a critical component of infrastructure development, supporting transportation, utility services, and even housing. One of the most essential aspects of tunnel construction is the process of installing tunnel linings, which provide structural integrity and durability to these subterranean paths. At the heart of this process is tunnel lining formwork, a crucial technology that ensures the efficiency, safety, and precision of construction projects.

Understanding Tunnel Lining Formwork

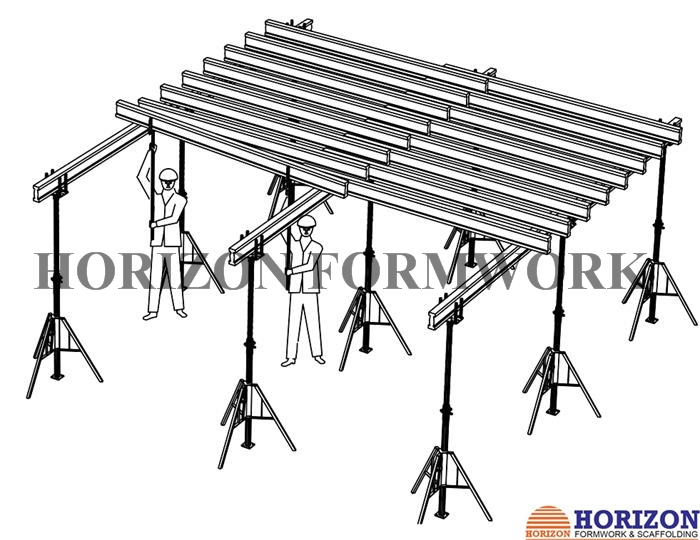

Tunnel lining formwork refers to the temporary structures that support the concrete or other materials used to create the inner surface of a tunnel. This formwork is essential for holding the shape of the tunnel during the curing process of the concrete. It can be designed in various forms depending on the tunnel’s size, shape, and expected loads. The primary purposes of formwork are to provide a mold for the concrete, maintain alignment, and prevent deformation during the setting process.

Types of Tunnel Lining Formwork

Various types of tunnel lining formwork systems are utilized in modern construction

. The most common include1. Traditional Timber Formwork Often used in smaller projects, this method involves creating wooden molds to shape the tunnel lining. While it’s relatively inexpensive and easy to construct, it is not as durable or efficient for larger tunnel projects.

2. Steel Formwork Steel systems are more robust and can be reused multiple times, which makes them cost-effective for large-scale operations. They provide a high level of precision and are particularly useful in urban environments where space constraints are prevalent.

3. Precast Concrete Formwork This method involves casting concrete elements in a controlled environment before transporting and assembling them within the tunnel. This approach enhances quality control and allows for rapid installation, significantly speeding up the construction timeline.

china tunnel lining formwork

4. Modular Formwork Modular systems consist of interlocking components that can be easily assembled and customized on-site. They are highly adaptable, allowing construction teams to respond effectively to different tunnel geometries.

The Importance of Formwork in Tunnel Construction

The significance of tunnel lining formwork extends beyond mere support for curing concrete. It plays a vital role in ensuring the structural safety and longevity of tunnels. Properly designed and executed formwork systems reduce the risk of structural failures, such as cracking or shifting, which can lead to costly repairs and safety hazards.

Moreover, innovative formwork solutions have led to reduced labor costs and faster project completion. Speedy installation of the formwork allows for quicker concrete pouring and curing, enabling projects to progress without unnecessary delays. In an industry where time is money, the efficiency gains from using advanced formwork systems can significantly improve project profitability.

Challenges and Innovations

Despite its importance, tunnel lining formwork is not without challenges. Issues such as formwork collapse, misalignment, and water leakage can jeopardize the integrity of the construction process. To combat these challenges, engineers continuously explore innovative materials and technologies.

One area of innovation is the use of smart formwork systems equipped with sensors to monitor pressure and temperature. This technology can provide real-time data to ensure the safety and effectiveness of the formwork. Additionally, advances in materials such as lightweight composites are making formwork systems easier to handle and install, further enhancing safety on job sites.

Conclusion

As urban populations grow and the demand for efficient transportation networks increases, the role of tunnel lining formwork in construction becomes ever more critical. By ensuring the structural integrity and efficiency of tunnels, formwork not only contributes to the successful completion of projects but also paves the way for future developments in civil engineering. As technology continues to evolve, embracing innovation in formwork solutions will be essential in meeting the challenges of modern infrastructure demands.

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025