Dec . 12, 2024 20:38 Back to list

formwork for floor slab company

Formwork for Floor Slabs A Comprehensive Guide

In the construction industry, the importance of formwork cannot be understated. It serves as the temporary structure that holds concrete in place until it achieves sufficient strength to support its own weight. One of the critical applications of formwork is in the construction of floor slabs, which are fundamental to the building's stability and usability. This article will explore the various types of formwork used for floor slabs, the advantages they offer, and the best practices for successful implementation.

Understanding Formwork

Formwork refers to the mold or framework used to shape and support concrete until it hardens. The materials utilized for formwork can range from traditional wood to modern day prefabricated systems using steel or aluminum. Choosing the right type of formwork is essential for optimizing project efficiency, ensuring safety, and maintaining cost-effectiveness.

Types of Formwork for Floor Slabs

1. Timber Formwork This is one of the most commonly used types of formwork, especially for small to medium-sized projects. Timber is easily available and allows for flexibility in shaping and sizing. However, timber formwork often requires more labor and time for installation and dismantling.

2. Steel Formwork Known for its strength and durability, steel formwork can be reused multiple times, making it a cost-effective choice for large-scale projects. It provides excellent dimensional accuracy and smooth finishes, making it ideal for structures where aesthetics are important.

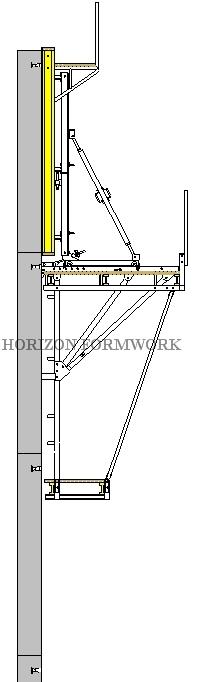

3. Aluminum Formwork This lightweight formwork is gaining popularity due to its ease of handling and installation. Aluminum formwork is reusable and can be prefabricated to reduce labor costs and time on site. It is particularly beneficial for high-rise buildings, where rapid construction times are essential.

4. Plastic Formwork A newer innovation in formwork technology, plastic formwork is lightweight, easy to clean, and durable. It is designed for quick assembly and disassembly, making it ideal for projects that require repetition and consistency.

Advantages of Using Formwork

formwork for floor slab company

2. Quality of Finish Using high-quality formwork ensures that the final concrete slab achieves the desired finish and dimensional accuracy, which is crucial for both aesthetics and functionality.

3. Cost Efficiency While the initial investment in formwork can be significant, the potential for reusability in systems like steel or aluminum can lead to substantial savings in the long term.

4. Time Savings Modern formwork systems are designed for rapid assembly and disassembly, allowing for quicker project timelines and reduced labor costs.

Best Practices for Formwork Installation

1. Plan Thoroughly Before commencing work, a detailed plan should be devised that includes the layout, materials, and construction methods for the formwork. This helps in avoiding errors and ensures that the project runs smoothly.

2. Follow Industry Standards Adhering to local and international standards for formwork design and construction ensures safety and reliability in the structural performance of the concrete slab.

3. Regular Inspections Frequent checks of the formwork during construction can help to identify potential issues early, avoiding costly delays or rework.

4. Work with Professionals Engaging experienced professionals for formwork design and construction can enhance the quality and efficiency of the project.

Conclusion

Formwork for floor slabs is a critical aspect of any construction project. With various options available—from timber to steel and aluminum—each type of formwork offers unique benefits that can be aligned with specific project needs. By employing best practices in planning, installation, and inspection, construction firms can ensure not only the stability and safety of their structures but also enhance the overall efficiency of their projects. In an industry where time and cost management are crucial, making informed choices about formwork can significantly bolster a company’s performance in the competitive construction landscape.

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025