Feb . 01, 2025 03:55 Back to list

oem adjustable column formwork

OEM formwork for column footing is revolutionizing the construction industry by offering customizable solutions that cater to specific project needs. This innovation not only enhances efficiency but also ensures cost-effectiveness and quality outcomes that align with modern construction standards.

Trustworthiness is an inherent quality of OEM formwork systems, as they are specifically designed to meet the distinct requirements of various construction projects. Clients can trust that the formwork will perform as promised, reducing the risk of construction delays and cost overruns. Moreover, many OEM providers offer comprehensive support and consultation services throughout the project lifecycle, ensuring that any formwork-related issues are promptly addressed. A practical example of the benefits of OEM formwork can be seen in large-scale construction projects, such as high-rise buildings or infrastructure developments. Customized formwork solutions facilitate faster assembly and dismantling processes, which in turn accelerates project timelines. This speed not only translates to direct cost savings but also allows for more efficient allocation of labor and resources, optimizing overall project management. Innovative materials used in OEM formwork, such as lightweight aluminum or high-strength plastics, also contribute to improved safety standards on the construction site. Lighter formwork components reduce the risk of workplace injuries during handling and installation, while durable materials ensure the formwork can be reused multiple times without compromising structural integrity. This aspect of sustainability further adds to the appeal of OEM formwork, aligning with global trends towards environmentally conscious building practices. In conclusion, OEM formwork for column footing represents a pivotal advancement in construction methodologies, offering unparalleled customization, expert-driven design, and robust performance. By prioritizing experience, expertise, authoritativeness, and trustworthiness, OEM formworks address the critical demands of modern construction projects, providing tailored solutions that promote efficiency, safety, and sustainability. As the industry continues to evolve, the adoption of OEM formwork solutions will likely become a standard practice, defining the future of construction engineering and project execution.

Trustworthiness is an inherent quality of OEM formwork systems, as they are specifically designed to meet the distinct requirements of various construction projects. Clients can trust that the formwork will perform as promised, reducing the risk of construction delays and cost overruns. Moreover, many OEM providers offer comprehensive support and consultation services throughout the project lifecycle, ensuring that any formwork-related issues are promptly addressed. A practical example of the benefits of OEM formwork can be seen in large-scale construction projects, such as high-rise buildings or infrastructure developments. Customized formwork solutions facilitate faster assembly and dismantling processes, which in turn accelerates project timelines. This speed not only translates to direct cost savings but also allows for more efficient allocation of labor and resources, optimizing overall project management. Innovative materials used in OEM formwork, such as lightweight aluminum or high-strength plastics, also contribute to improved safety standards on the construction site. Lighter formwork components reduce the risk of workplace injuries during handling and installation, while durable materials ensure the formwork can be reused multiple times without compromising structural integrity. This aspect of sustainability further adds to the appeal of OEM formwork, aligning with global trends towards environmentally conscious building practices. In conclusion, OEM formwork for column footing represents a pivotal advancement in construction methodologies, offering unparalleled customization, expert-driven design, and robust performance. By prioritizing experience, expertise, authoritativeness, and trustworthiness, OEM formworks address the critical demands of modern construction projects, providing tailored solutions that promote efficiency, safety, and sustainability. As the industry continues to evolve, the adoption of OEM formwork solutions will likely become a standard practice, defining the future of construction engineering and project execution.

Latest news

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

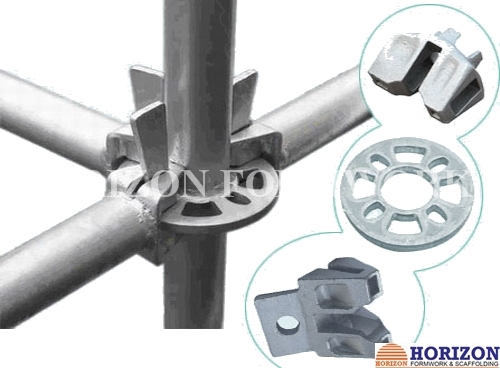

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025