Dec . 01, 2024 00:10 Back to list

Top Exporters of Automatic Climbing Formwork for Construction Projects Worldwide

Understanding Automatic Climbing Formwork A Comprehensive Overview for Exporters

In recent years, the construction industry has witnessed a significant transformation with the introduction of advanced technologies designed to enhance efficiency and safety on construction sites. Among these innovations, automatic climbing formwork systems have gained popularity due to their ability to streamline the construction process, particularly in high-rise buildings. For exporters, understanding the intricacies of automatic climbing formwork is essential to meet the growing international demand while ensuring compliance with varying standards and regulations.

What is Automatic Climbing Formwork?

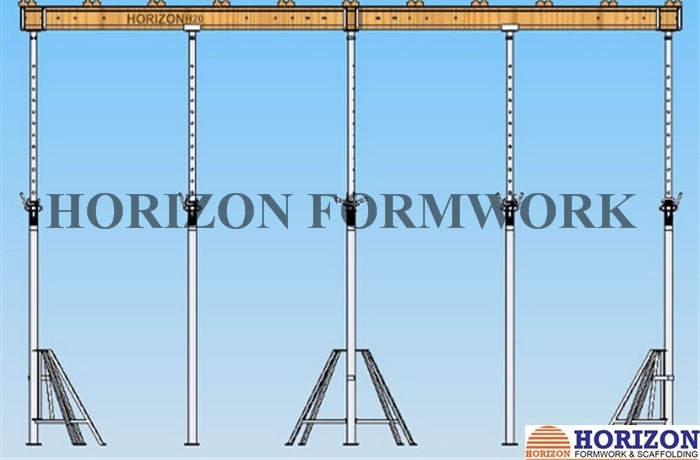

Automatic climbing formwork is an innovative construction method that employs a self-climbing system to support concrete structures during the pouring and setting process. Unlike traditional formwork systems, which require manual labor to install and dismantle, automatic climbing formwork allows for efficient vertical climbing. This system is often used in projects involving tall structures such as skyscrapers, bridges, and dams, where height and safety become critical factors.

The key components of automatic climbing formwork include a climbing frame, hydraulic jacks, and a set of form panels. Once the concrete is poured and properly set, the hydraulic jacks elevate the entire formwork system to the next level, allowing construction to continue seamlessly.

Benefits of Automatic Climbing Formwork

The automatic climbing formwork system presents numerous advantages for construction projects, making it an attractive choice for contractors and builders. Some of these benefits include

1. Increased Efficiency The automation reduces the labor required for formwork setup and removal, resulting in shorter project timelines. The ability to climb quickly between levels allows for continuous construction without delays.

2. Enhanced Safety With fewer workers required at heights to install or remove formwork, the risk of accidents and injuries decreases significantly. The built-in safety features of climbing formwork systems further promote worker safety.

3. Improved Quality Since the formwork is mechanically controlled, it ensures greater precision in the construction process. Uniformity of the final structure is easier to maintain, leading to improved overall quality.

automatic climbing formwork exporters

5. Environmentally Friendly By minimizing waste and reducing the need for multiple formwork setups, this system is more environmentally sustainable than its traditional counterparts.

Global Market Trends and Export Opportunities

As urbanization continues to rise globally, the demand for efficient construction solutions is increasing. Markets in Asia-Pacific, Europe, and North America are particularly ripe for the introduction of automatic climbing formwork systems, driven by skyscraper projects and large infrastructure undertakings.

Exporters looking to enter this market should consider a few essential aspects

1. Compliance with Standards Each country may have specific regulations governing construction methods and materials. Exporters must ensure that their formwork systems comply with local standards to avoid legal issues.

2. Local Partnerships Establishing partnerships with local construction firms can facilitate market entry. Collaborations can also provide valuable insights into regional construction practices and preferences.

3. Technological Adaptation Different markets may have varying technological needs and preferences. Adapting the design and functionality of the automatic climbing formwork to meet these local demands will help improve acceptance.

4. Comprehensive Training Offering training programs for workers and engineers on how to safely and efficiently use automatic climbing formwork can enhance its acceptance and usability in new markets.

5. Marketing and Education As this technology might be new to some markets, creating informative marketing materials and conducting workshops can help educate potential clients about the benefits and capabilities of automatic climbing formwork systems.

Conclusion

The automatic climbing formwork revolutionizes the construction industry, offering increased efficiency, safety, and environmental sustainability. For exporters, navigating the demands of this growing market requires understanding its unique challenges and opportunities. By focusing on compliance, local partnerships, and comprehensive support, exporters can successfully introduce automatic climbing formwork systems to diverse global markets, ultimately contributing to the advancement of modern construction techniques.

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025

-

China Single Sided Wall Formwork: Fast, Flexible Solutions

NewsAug.14,2025