dec . 14, 2024 01:33 Back to list

formworks for beams manufacturers

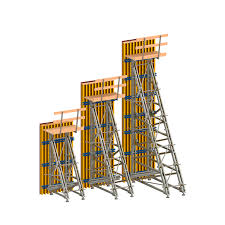

Formworks for Beam Manufacturing A Comprehensive Overview

Formwork is an essential component in the process of beam manufacturing, providing the support and shape necessary for concrete to achieve its final form. As the construction industry continues to evolve, the demand for innovative, efficient, and sustainable formwork solutions grows. This article explores various types of formworks used in beam manufacturing, their benefits, and the factors influencing their selection.

Understanding Formwork

Formwork refers to molds that provide temporary or permanent support for concrete during its curing process. In the context of beam manufacturing, formwork ensures that the concrete retains its intended shape, strength, and durability while it sets. There are two primary types of formwork traditional timber formwork and modern engineered systems.

Types of Formworks

1. Timber Formwork This is the traditional method, utilizing wooden planks and boards. Timber formwork is cost-effective and relatively easy to assemble. However, it often requires skilled labor and can be time-consuming in terms of setup and dismantling.

2. Steel Formwork This method uses steel panels, providing a sturdier and reusable alternative to timber. Steel formwork is advantageous for high-quality finishes and can withstand multiple uses, making it economical in the long run despite a higher initial cost.

3. Aluminium Formwork Known for its lightweight properties, aluminum formwork offers easy handling and setup. It is highly durable and can be customized for complex shapes. Its quick installation process makes it a popular choice for large-scale projects.

4. Plastic Formwork Emerging as a sustainable option, plastic formwork is lightweight, reusable, and often made from recycled materials. It is particularly suitable for smaller projects and can adapt to various designs.

5. Precast Formwork Systems This innovative approach involves casting beams off-site in controlled environments. Precast formwork allows for superior quality control, reduces project timelines, and minimizes on-site labor.

Benefits of Using Modern Formwork Systems

The choice of formwork significantly impacts the efficiency, safety, and quality of beam manufacturing

. Modern formwork systems offer several advantagesformworks for beams manufacturers

- Enhanced Safety Advanced formwork designs often include built-in safety features that reduce risks associated with construction work.

- Increased Speed Quick assembly and disassembly capabilities of modern materials allow projects to adhere to tight schedules, enhancing cost-efficiency.

- Quality Control Engineered formworks come with precision manufacturing, ensuring that beams are produced with consistent dimensions and strength.

- Sustainability Many modern formwork options prioritize environmental considerations, utilizing recyclable materials and reducing waste.

Selecting the Right Formwork

When choosing the appropriate formwork for beam manufacturing, several factors should be considered

- Project scale and complexity The size and design of the beams dictate the suitable formwork type. Complex designs may require more versatile forms.

- Budget constraints Initial costs often differ significantly between timber, steel, aluminum, and plastic formwork, influencing the decision based on available budgets.

- Labor resources The availability of skilled labor can affect the choice of formwork, with some systems requiring specialized knowledge for installation.

- Environmental considerations Increasingly, organizations are focusing on sustainability, opting for eco-friendly formwork options that align with green construction practices.

Conclusion

In conclusion, formworks play a critical role in the manufacturing of beams within the construction industry. As technology advances, the diversity of formwork systems available ensures that manufacturers can select solutions that best meet their specific needs. By understanding the benefits and drawbacks of various formwork types, stakeholders can optimize their construction processes, improve safety standards, and reduce environmental impact while achieving high-quality results.

-

High Quality Climbing Formwork for High-Rise Building & Core Wall Solutions

NewsJul.25,2025

-

High-Quality Slab Formwork Solutions for Efficient Construction

NewsJul.24,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.23,2025

-

Climbing Formwork Solutions for High-Rise Construction Efficiency

NewsJul.22,2025

-

Premium Table Formwork for Slab Construction | Reusable & OEM Support

NewsJul.22,2025

-

Heavy Duty Props EN1065 Certified - Adjustable Steel Shoring for Formwork

NewsJul.21,2025