Oktoba . 11, 2024 18:08 Back to list

Metal Frame Scaffolding Manufacturing Companies and Their Key Offerings

The Importance of Metal Frame Scaffolding Factories in Modern Construction

In today’s rapidly evolving construction industry, safety and efficiency are paramount. One of the key components that ensure both is the scaffolding system used at job sites. Among the various types of scaffolding, metal frame scaffolding has gained immense popularity due to its durability, flexibility, and ease of assembly. Behind this essential component lies a network of specialized factories dedicated to manufacturing high-quality metal frame scaffolding.

What is Metal Frame Scaffolding?

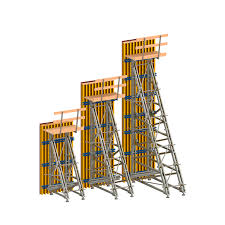

Metal frame scaffolding refers to a temporary structure made of steel or aluminum, designed to provide support and access to workers, materials, and equipment during construction or maintenance activities. Unlike traditional wooden scaffolding, metal frame scaffolding offers greater strength and stability, making it suitable for a variety of applications, from residential buildings to large-scale commercial projects.

The Role of Metal Frame Scaffolding Factories

Factories that specialize in metal frame scaffolding play a crucial role in the construction supply chain. They are responsible for the production of high-quality, standardized scaffolding systems that adhere to safety regulations and industry standards. The manufacturing process involves the use of advanced technology and skilled labor to create robust frame components, fittings, and accessories that can withstand significant loads and adverse conditions.

Key Features of Metal Frame Scaffolding

1. Durability Metal scaffolding is designed to endure heavy loads and harsh weather conditions. Factories typically utilize galvanized or powder-coated steel to prevent corrosion, ensuring longevity and reliability.

2. Modularity The modular design of metal frame scaffolding allows for easy customization and assembly, making it ideal for various construction projects. This adaptability reduces the time and labor needed for setup and takedown.

metal frame scaffolding factories

3. Safety Safety is a top priority in construction, and metal frame scaffolding is often equipped with guardrails, toe boards, and other safety features to protect workers on site. Factories invest in rigorous testing to ensure that their products meet safety standards.

4. Cost-Effectiveness While the initial investment in metal scaffolding may be higher than traditional wood scaffolding, its durability and reusability lead to lower long-term costs. Many factories also offer rental options, making it accessible for smaller contractors.

The Manufacturing Process

The manufacturing process of metal frame scaffolding typically begins with the sourcing of raw materials. Factories procure high-quality steel or aluminum, which is then cut, shaped, and welded into various components. Advanced machinery, such as CNC cutting machines and hydraulic benders, ensures precise manufacturing standards. Quality control is an essential aspect of the process, with inspections conducted at multiple stages to maintain the structural integrity of the products.

After the scaffolding components are manufactured, they undergo finishing processes, including galvanization or powder coating, to enhance corrosion resistance and aesthetic appeal. Finally, the completed scaffolding systems are packaged and prepared for distribution to construction sites around the world.

The Future of Metal Frame Scaffolding Factories

As the construction industry continues to advance, the demand for metal frame scaffolding is expected to grow. Factors such as urbanization, infrastructure development, and a focus on sustainable building practices will contribute to this trend. Factories are now exploring innovative designs and smart technologies to enhance the functionality of scaffolding systems. Additionally, the adoption of eco-friendly materials and manufacturing processes aligns with the global push towards sustainability in construction.

Conclusion

Metal frame scaffolding factories play a vital role in the construction industry, providing essential products that enhance safety and productivity on job sites. With the continuous evolution of construction practices, these factories are poised to adapt and innovate, ensuring that they meet the needs of a dynamic market while upholding the highest standards of quality and safety. As such, the metal frame scaffolding industry will remain a cornerstone of modern construction, contributing to the successful completion of projects worldwide.

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025