Januari . 20, 2025 09:28 Back to list

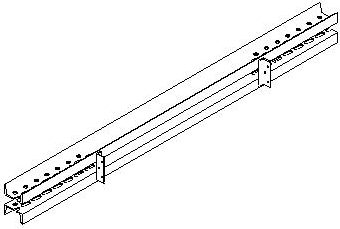

oem adjustable column formwork

The OEM column system formwork is revolutionizing the construction industry, bringing innovations that merge efficiency, safety, and cost-effectiveness in a single package. This breakthrough in construction technology offers a tailored solution that addresses diverse structural requirements, providing significant competitive advantages for both contractors and developers.

Trustworthiness is further bolstered through comprehensive support and training offered by OEM providers. Continuous professional development and guided training sessions ensure that all personnel involved in the deployment of column formwork are fully equipped with the necessary skills and knowledge. This commitment to education safeguards against potential misuse or misunderstandings related to the system's application. Moreover, an often-overlooked advantage of utilizing the OEM column system formwork is its contribution to sustainability in construction. Its reusable components reduce material consumption and support waste reduction strategies, aligning with global sustainability goals. Construction firms adopting this system report not only operational efficiencies but also enhanced corporate responsibility profiles. Feedback from the field demonstrates a high satisfaction rate among users who have implemented the OEM column system formwork. Its innovative design and implementation reduce not only direct costs but also ancillary expenses associated with delays and safety incidents. This holistic benefit extends beyond immediate financial considerations, fostering long-term relationships with clients through superior quality and reliability. In summation, the OEM column system formwork represents a significant leap forward in construction methodology. Its strategic blend of customization, efficiency, and sustainability offers unparalleled advantages to construction professionals. By addressing both present needs and future challenges, it positions itself as a cornerstone in modern architectural practices, embodying a future-oriented approach that does not compromise on quality or safety. As these systems continue to evolve, their role in shaping the built environment will undoubtedly expand, driving innovation and setting new standards across the industry.

Trustworthiness is further bolstered through comprehensive support and training offered by OEM providers. Continuous professional development and guided training sessions ensure that all personnel involved in the deployment of column formwork are fully equipped with the necessary skills and knowledge. This commitment to education safeguards against potential misuse or misunderstandings related to the system's application. Moreover, an often-overlooked advantage of utilizing the OEM column system formwork is its contribution to sustainability in construction. Its reusable components reduce material consumption and support waste reduction strategies, aligning with global sustainability goals. Construction firms adopting this system report not only operational efficiencies but also enhanced corporate responsibility profiles. Feedback from the field demonstrates a high satisfaction rate among users who have implemented the OEM column system formwork. Its innovative design and implementation reduce not only direct costs but also ancillary expenses associated with delays and safety incidents. This holistic benefit extends beyond immediate financial considerations, fostering long-term relationships with clients through superior quality and reliability. In summation, the OEM column system formwork represents a significant leap forward in construction methodology. Its strategic blend of customization, efficiency, and sustainability offers unparalleled advantages to construction professionals. By addressing both present needs and future challenges, it positions itself as a cornerstone in modern architectural practices, embodying a future-oriented approach that does not compromise on quality or safety. As these systems continue to evolve, their role in shaping the built environment will undoubtedly expand, driving innovation and setting new standards across the industry.

Next:

Latest news

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025