Februari . 10, 2025 10:28 Back to list

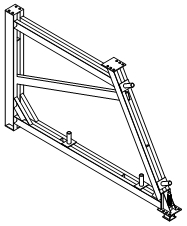

Climbing Formwork CB240

Navigating through the intricacies of the scaffolding industry can be quite a labyrinth, especially when dealing with the concept of OEM domestic scaffolding. For construction companies, contractors, and even end-users looking for reliable equipment, understanding OEM domestic scaffolding products is crucial. These products are fundamental in ensuring safety, efficiency, and cost-effectiveness in construction projects.

Furthermore, the customization offered by OEM scaffolding manufacturers allows construction companies to acquire solutions uniquely tailored to their project specifications. This adaptability extends to scaffolding dimensions, load capacities, and assembly configurations, empowering construction managers to optimize work efficiency and site safety effectively. An often-overlooked advantage of utilizing OEM domestic scaffolding is cost-effectiveness. While the initial investment might be higher compared to generic scaffolding solutions, the long-term benefits—reduced downtime due to fewer accidents, lower maintenance costs, and prolonged lifespan—make it a financially sound decision. OEM scaffolding reduces the total cost of ownership by minimizing the need for frequent replacements or repairs, which can be both costly and time-consuming. The value of OEM scaffolding transcends basic usability. Its design precision, high-quality manufacturing process, and ability to meet complex project requirements position it as a critical resource in today's construction environment. As projects become more intricate and demand greater safety measures, the reliance on OEM domestic scaffolding is poised to increase, reflecting a trend towards more reliable and customized construction solutions. Key industry insights reveal that leveraging OEM domestic scaffolding not only elevates the safety standards of a project but also enhances operational efficiency. Companies that have embraced these scaffolding solutions consistently report improved project timelines, fewer safety incidents, and reduced operational costs, contributing to overall project success and client satisfaction. In conclusion, OEM domestic scaffolding emerges as a pivotal element in the construction landscape, combining engineering excellence with the flexibility required to address unique construction challenges. As the construction industry continues to evolve, the expertise and dependability of OEM scaffolding systems will undoubtedly remain a cornerstone of safe and efficient building practices, ultimately defining the future of construction dynamics.

Furthermore, the customization offered by OEM scaffolding manufacturers allows construction companies to acquire solutions uniquely tailored to their project specifications. This adaptability extends to scaffolding dimensions, load capacities, and assembly configurations, empowering construction managers to optimize work efficiency and site safety effectively. An often-overlooked advantage of utilizing OEM domestic scaffolding is cost-effectiveness. While the initial investment might be higher compared to generic scaffolding solutions, the long-term benefits—reduced downtime due to fewer accidents, lower maintenance costs, and prolonged lifespan—make it a financially sound decision. OEM scaffolding reduces the total cost of ownership by minimizing the need for frequent replacements or repairs, which can be both costly and time-consuming. The value of OEM scaffolding transcends basic usability. Its design precision, high-quality manufacturing process, and ability to meet complex project requirements position it as a critical resource in today's construction environment. As projects become more intricate and demand greater safety measures, the reliance on OEM domestic scaffolding is poised to increase, reflecting a trend towards more reliable and customized construction solutions. Key industry insights reveal that leveraging OEM domestic scaffolding not only elevates the safety standards of a project but also enhances operational efficiency. Companies that have embraced these scaffolding solutions consistently report improved project timelines, fewer safety incidents, and reduced operational costs, contributing to overall project success and client satisfaction. In conclusion, OEM domestic scaffolding emerges as a pivotal element in the construction landscape, combining engineering excellence with the flexibility required to address unique construction challenges. As the construction industry continues to evolve, the expertise and dependability of OEM scaffolding systems will undoubtedly remain a cornerstone of safe and efficient building practices, ultimately defining the future of construction dynamics.

Next:

Latest news

-

Reliable China Single Sided Wall Formwork Manufacturer

NewsAug.12,2025

-

Formwork Wing Nut | Quality Tie Rod & Water Stop Supplier

NewsAug.11,2025

-

Durable Steel Prop with Tripod for Stable Support

NewsAug.10,2025

-

OEM Column Formwork: Custom, Circular, Curved & Adjustable

NewsAug.09,2025

-

Custom OEM Column Formwork | Versatile & Efficient Solutions

NewsAug.08,2025

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025