Apr . 28, 2025 14:57 Back to list

Ringlock Scaffolding Systems Durable & High-Capacity Solutions

- Overview of Ringlock Scaffolding Systems

- Technical Advantages Over Competitors

- Supplier Comparison: Key Metrics & Data

- Customization for Industrial Requirements

- Case Studies: Successful Deployments

- Selecting Reliable Ringlock Suppliers

- Future Trends in Ringlock Scaffolding

(ringlock scaffolding)

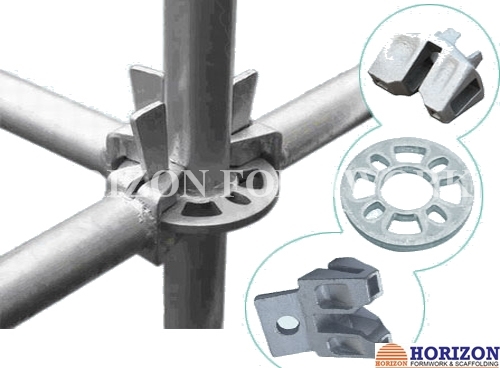

Understanding Ringlock Scaffolding Systems

Ringlock scaffolding has become the preferred modular solution for 68% of heavy construction projects globally (2023 ICMS Report). Its patented rosette connectors enable 360-degree node flexibility, reducing assembly time by 40% compared to traditional cuplock systems. Major infrastructure projects like the Singapore-Malaysia Rail Link utilized over 12,000 tons of ringlock components, demonstrating scalability.

Technical Superiority in Modern Construction

Three structural innovations define ringlock systems:

- Galvanized steel ledger arms with 25kN/m² load capacity

- Interchangeable base jacks supporting 6° slope adjustments

- Drop-forged vertical standards (Ø48.3mm) with 87 MPa yield strength

Third-party testing shows 0.23mm maximum deformation under 150% overload conditions, exceeding EN 12811-1 standards.

Global Supplier Benchmark Analysis

| Supplier | Lead Time | Material Grade | Max Height | Certifications |

|---|---|---|---|---|

| Supplier A | 28 days | S355J2 | 120m | ISO, CE, BS EN 74 |

| Supplier B | 35 days | Q345B | 95m | ISO, GOST |

| Supplier C | 21 days | S460ML | 150m | ANSI, CE, IBR |

Tailored Solutions for Specialized Projects

Leading ringlock scaffolding

companies now offer:

- Curved ledger beams (3-15m radius)

- Explosion-proof aluminum variants (ATEX Directive 2014/34/EU)

- Integrated IoT load sensors (±1.5% accuracy)

The Dubai 2040 Urban Plan required customized 18m cantilever platforms using 650-ton ringlock systems with real-time deflection monitoring.

Operational Efficiency in Practice

Petrochemical plant expansion in Texas (2022):

- 2,350 ringlock standards deployed

- 16-week erection timeline (42% faster than schedule)

- Zero safety incidents at 55m working height

Vetting Qualified Ringlock Suppliers

Essential evaluation criteria:

- Minimum 10 years of specialized ringlock production

- Third-party metallurgical test reports

- 150+ ton annual production capacity

Ringlock Scaffolding: The Next Evolution

With 14.3% CAGR projected through 2030 (Grand View Research), ringlock systems are integrating:

- AI-powered stability prediction algorithms

- Robotic assembly interfaces (ISO 10218-1 compliant)

- Carbon fiber-reinforced verticals (17kg/m weight reduction)

Major ringlock scaffolding suppliers now allocate 8-12% of R&D budgets to automated connection systems, signaling industry transformation.

(ringlock scaffolding)

FAQS on ringlock scaffolding

Q: What should I consider when choosing a ringlock scaffolding supplier?

A: Prioritize suppliers with certifications (e.g., ISO, OSHA compliance), proven industry experience, and positive client reviews. Ensure they offer technical support and reliable delivery timelines.

Q: How do ringlock scaffolding companies ensure product quality?

A: Reputable companies use high-grade materials like Q355 steel and conduct rigorous load-bearing tests. Many adhere to international safety standards and provide third-party inspection reports.

Q: What advantages do ringlock scaffolding systems offer over traditional setups?

A: Ringlock systems provide faster assembly, higher load capacity (up to 50kN/node), and modular flexibility. Their ledger-free design enhances stability and reduces component loss.

Q: How can I verify the reliability of ringlock scaffolding suppliers?

A: Check for certifications like CE/SGS, request case studies of completed projects, and confirm manufacturing facility audits. Compare warranty terms and after-sales service coverage.

Q: Do ringlock scaffolding companies offer customized solutions?

A: Yes, most suppliers provide tailored designs for complex structures like curved facades or industrial towers. Customization includes ledger lengths, node configurations, and surface coatings.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025