Dec . 23, 2024 11:29 Back to list

Concrete Formwork Block Manufacturing Industry Overview and Insights

The Role and Significance of Concrete Shuttering Blocks Factories

Concrete shuttering blocks play a critical role in the construction industry, serving as essential components in the building of structures. These blocks are primarily used in temporary forms for concrete, which supports the material while it sets and hardens. The production of these shuttering blocks is facilitated by specialized factories that focus on producing high-quality materials to meet the demands of various construction projects. This article delves into the significance of concrete shuttering blocks factories, their manufacturing process, and their impact on the construction landscape.

Understanding Shuttering Blocks

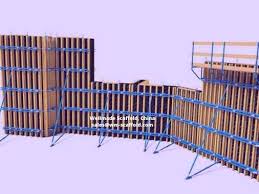

Shuttering blocks, often referred to as formwork blocks, are made from concrete, which is renowned for its durability and strength. These blocks create a mold for poured concrete, helping to shape the final product. They can be reused multiple times, making them a cost-effective solution for builders. Additionally, shuttering blocks are utilized in various applications, including walls, beams, columns, and slabs, making them versatile for different architectural designs.

The Manufacturing Process

The production of concrete shuttering blocks involves several steps. First, high-quality raw materials such as cement, aggregates, water, and admixtures are sourced. The right mix is crucial, as it determines the strength and durability of the blocks. Factories often employ modern technology to ensure a consistent mixture, which is then poured into molds. After being shaped, the blocks undergo curing, a vital process that allows the concrete to gain strength and durability.

Curing can take place in various environments; some factories use steam curing, while others may rely on water curing or air curing. The choice of curing method can significantly affect the final product's quality. Once cured, the blocks are tested for strength, density, and other properties to ensure they meet industry standards before being packaged and shipped to clients.

Importance of Quality Control

concrete shuttering blocks factories

Quality control is paramount in the manufacturing process of concrete shuttering blocks. Factories often implement rigorous testing protocols to ensure their products meet the required specifications. This includes compressive strength tests, absorption tests, and high-performance evaluations. By adhering to strict quality standards, manufacturers can reduce the risk of failures in construction projects, which can have severe safety and financial implications.

Environmental Considerations

Modern concrete shuttering blocks factories are increasingly focusing on sustainable practices. The construction industry is known for its environmental impact, and manufacturers are seeking ways to minimize this footprint. Some factories recycle concrete waste, use eco-friendly materials, and implement energy-efficient manufacturing processes. These sustainable practices not only contribute to environmental conservation but can also appeal to clients who prioritize green building initiatives.

Impact on the Construction Industry

The presence of concrete shuttering blocks factories significantly influences the construction sector. By providing high-quality, ready-to-use materials, these factories help streamline the construction process, reducing labor costs and project timelines. The availability of reliable shuttering blocks allows constructors to complete their projects more efficiently while maintaining structural integrity.

Moreover, with the rise of urbanization and infrastructure projects worldwide, the demand for concrete shuttering blocks is on the rise. Factories are expanding their production capacities and innovating their designs to cater to various architectural needs. As cities grow and the need for infrastructure increases, the role of shuttering blocks in construction becomes increasingly vital.

Conclusion

Concrete shuttering blocks factories are essential players in the construction industry, providing necessary materials that enhance efficiency and safety in building projects. With a focus on quality and sustainability, these factories not only support the growing demand for infrastructure but also contribute to the long-term viability of construction practices. As technology advances and environmental considerations become more critical, the manufacturing of concrete shuttering blocks will continue to evolve, ensuring that the industry meets the challenges of the future while promoting sustainable development.

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025