Nov . 14, 2024 16:22 Back to list

galvanized metal scaffolding exporters

Exploring the Market for Galvanized Metal Scaffolding Exporters

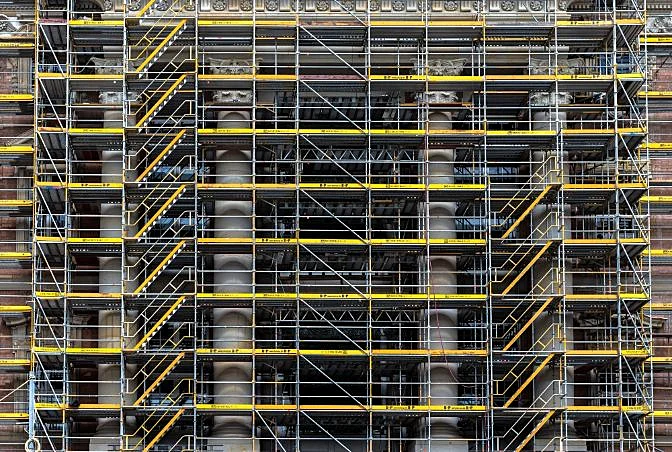

In the construction industry, safety and reliability are paramount. This is where galvanized metal scaffolding comes into play. Galvanized scaffolding is steel intermediate supports that have been coated with a protective layer of zinc to enhance their strength and corrosion resistance. As urban construction skyrockets globally, the demand for quality scaffolding solutions, particularly galvanized metal scaffolding, has witnessed a substantial increase. In this article, we will explore the importance of this material, the landscape of its export market, and the key players involved in its distribution.

The Importance of Galvanized Metal Scaffolding

Galvanized metal scaffolding is an essential part of construction projects. It is used to provide temporary support and a safe working platform for workers. The galvanization process not only adds a layer of durability and rust prevention but also extends the lifespan of the scaffolding, making it a cost-effective solution for construction companies. The ability of galvanized scaffolding to withstand harsh weather conditions makes it particularly popular in areas with high humidity or rainfall, which could otherwise lead to premature deterioration of regular steel scaffolding.

Furthermore, the modular design of galvanized scaffolding allows for easy assembly and disassembly, enabling faster project completion. This flexibility is particularly important in an industry where time is money. In addition, the lightweight nature of galvanized scaffolding increases its transport efficiency, making it suitable for exporters who need to ship materials across borders, often at a reduced cost.

The Export Market Dynamics

With the global push for infrastructure development, the market for galvanized metal scaffolding has expanded beyond domestic borders. Countries undergoing rapid urbanization, such as India, China, and Brazil, are key players in the demand for exporting scaffolding materials. However, developed nations, such as the United States and Germany, are also significant importers, looking to procure high-quality scaffolding from reliable suppliers.

galvanized metal scaffolding exporters

Exporters of galvanized metal scaffolding must navigate several challenges, including adherence to international quality standards, logistics, and varying regulations across different countries. Successful exporters often invest in certifications and compliance measures, ensuring that their products meet the safety and durability standards required by the importing countries. Additionally, understanding the competitive landscape and pricing strategies in target markets can significantly influence an exporter's success.

Key Players and Trends

The market for galvanized metal scaffolding is filled with numerous exporters, manufacturers, and suppliers. Some of the key players have established a strong reputation by focusing on quality, innovation, and customer service. Companies that innovate in terms of design and functionality—like offering adjustable scaffolding systems or incorporating advanced materials—are at the forefront of this market.

Furthermore, sustainability trends are increasingly influencing the industry. Exporters are now looking to promote eco-friendly practices by opting for sustainable materials and production processes. This shift aligns well with global efforts toward reducing carbon footprints and promoting environmental responsibility in the construction sector.

Technological advancements, such as those in manufacturing processes and logistics, are also shaping the landscape for exporters. With the rise of e-commerce, many scaffolding exporters are resorting to online platforms to reach international customers, improving visibility and accessibility.

Conclusion

The market for galvanized metal scaffolding exporters presents significant opportunities driven by the ever-growing demand for construction materials globally. As the importance of safety, durability, and flexibility in construction practices becomes increasingly clear, galvanized scaffolding will continue to gain traction. Exporters must remain agile, investing in quality assurance and innovative practices while navigating the challenges of international trade. The future looks bright for galvanized metal scaffolding as it plays a pivotal role in shaping the infrastructure of tomorrow.

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025