Aug . 30, 2024 17:34 Back to list

modular formwork for concrete suppliers

Modular Formwork for Concrete Suppliers Revolutionizing Construction Efficiency

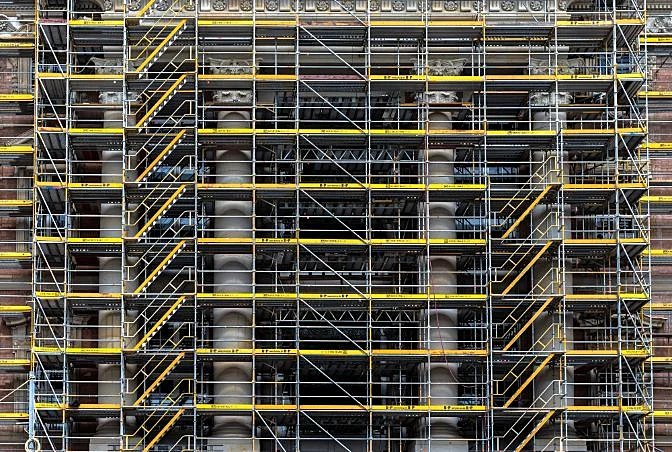

In recent years, the construction industry has witnessed significant advancements in techniques and materials that enhance efficiency and reduce costs. One of the most impactful innovations is modular formwork systems designed for concrete suppliers. Modular formwork offers a versatile and efficient solution for construction projects, streamlining the process of pouring concrete and shaping structures.

Modular Formwork for Concrete Suppliers Revolutionizing Construction Efficiency

One of the most significant advantages of modular formwork is its time-saving capabilities. Traditional formwork may require days or even weeks to set up, whereas modular systems can be assembled in a fraction of that time. This expedited process not only accelerates project timelines but also reduces labor costs, making it an appealing option for both contractors and concrete suppliers. As the construction industry faces increasing pressure to deliver projects on time and within budget, adopting modular formwork can provide a competitive edge.

modular formwork for concrete suppliers

Furthermore, modular formwork solutions are often lighter and made from more durable materials than traditional alternatives. Many modern systems utilize high-strength aluminum or plastic, which are easier to handle and transport. This reduction in weight lowers the risk of injury for workers while also minimizing transportation costs. Additionally, these materials are resistant to environmental factors, ensuring long-lasting performance and a lower frequency of repairs or replacements.

Sustainability is another critical factor in today's construction industry. Modular formwork contributes to environmentally friendly building practices by reducing waste generated during the construction process. Because these systems are reusable, they can be employed for multiple projects, significantly decreasing the amount of material expended. By choosing modular formwork, concrete suppliers can align with green building initiatives, appealing to eco-conscious clients and enhancing their marketability.

Moreover, technology plays a pivotal role in the evolution of modular formwork systems. Advanced design software allows for precise planning and visualization of projects, ensuring that formwork fits perfectly and reducing the potential for errors during construction. The integration of digital tools into the process allows for more innovative designs and efficient workflows, ensuring that concrete suppliers can meet the demands of modern architectures and construction methods.

In conclusion, modular formwork represents a significant advancement in the concrete supply chain, offering construction professionals a versatile, efficient, and sustainable option. As the industry continues to evolve, embracing these innovative systems will be crucial for suppliers to remain competitive, meet client expectations, and contribute to a more sustainable future in construction. With the continued evolution of modular systems, the sky is truly the limit for what can be achieved in today’s dynamic building landscape.

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025