Ara . 06, 2024 04:14 Back to list

Innovative Solutions in Concrete Formwork Engineering for Modern Construction Projects

Concrete Formwork Engineering Factory A Pillar of Modern Construction

In today’s rapidly evolving construction landscape, concrete formwork engineering has emerged as a cornerstone of architectural innovation and structural integrity. A concrete formwork engineering factory plays a crucial role in this industry, supplying essential components that enable builders and contractors to execute their projects efficiently and effectively. This article delves into the significance of concrete formwork, the operations within a formwork factory, and the impact it has on the construction sector.

Understanding Concrete Formwork

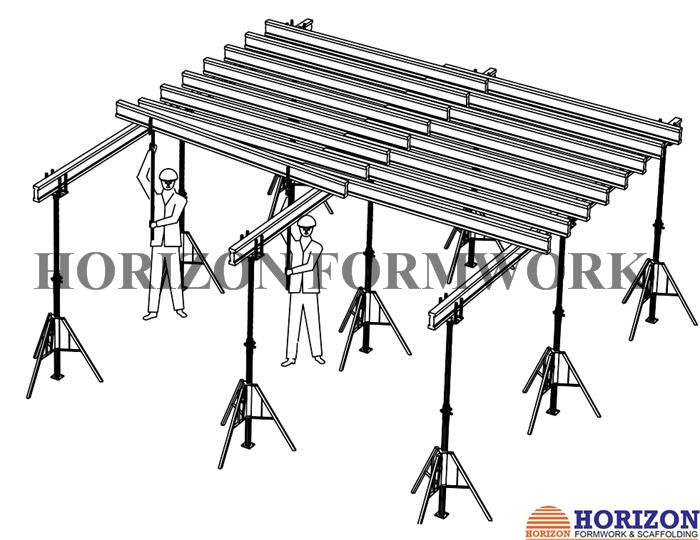

Concrete formwork refers to the temporary structures that hold concrete in place while it sets and hardens. This process is fundamental to creating the shapes and designs required for concrete structures such as walls, beams, columns, and slabs. The quality of formwork directly affects the final outcome of a construction project, making it imperative for builders to invest in high-quality materials and designs.

Formwork can be made from various materials, including wood, steel, aluminum, and plastic. Each material has its advantages and disadvantages, influencing factors like weight, cost, durability, and ease of use. However, regardless of the material used, the primary objective remains the same to ensure that the concrete is placed accurately and retains its shape until it reaches sufficient strength.

The Operations of a Formwork Factory

A concrete formwork engineering factory combines advanced technology and skilled labor to manufacture formwork systems that meet diverse construction needs. The factory's operations typically begin with the design phase, where engineers and architects collaborate to create formwork designs tailored to specific projects. This phase is critical as it determines the effectiveness and efficiency of the formwork in real-world applications.

Once the design is finalized, the factory begins the manufacturing process. This involves cutting, shaping, and assembling the chosen materials into formwork systems. Advanced machinery, such as CNC routers and automated cutting tools, enhance precision and reduce production time. Furthermore, quality control is paramount; each piece of formwork undergoes rigorous inspections to ensure it meets safety standards and performs as expected.

The logistics aspect of a concrete formwork factory cannot be overlooked. After production, the formwork systems need to be efficiently transported to construction sites. Effective supply chain management ensures timely delivery, allowing projects to stay on schedule and minimizing delays.

concrete formwork engineering factory

The Impact on Construction Projects

The influence of a concrete formwork engineering factory extends beyond just providing materials; it significantly impacts the overall construction process. High-quality formwork leads to improved concrete finishes, reducing the need for additional treatments and repairs post-construction. Moreover, efficient formwork systems can lead to faster construction times, thus reducing project costs.

With the increasing emphasis on sustainability in construction, many factories are now focusing on eco-friendly practices. This includes using recyclable materials for formwork and implementing energy-efficient manufacturing processes. By prioritizing sustainability, these factories contribute to the global efforts in reducing the carbon footprint of construction activities.

Future Trends in Formwork Engineering

As the construction industry progresses, so too does the field of concrete formwork engineering. Innovations such as modular formwork systems and the use of advanced materials are gaining popularity. Modular systems allow for quick assembly and disassembly, making them ideal for projects with tight deadlines. Similarly, the introduction of lightweight materials enhances portability and reduces labor costs.

In addition, the integration of technology, such as Building Information Modeling (BIM), is transforming how formwork is designed and manufactured. BIM-enabled design processes offer enhanced accuracy and facilitate better collaboration among stakeholders, ultimately leading to more successful project outcomes.

Conclusion

In summary, a concrete formwork engineering factory is an integral part of modern construction. By producing high-quality, innovative formwork solutions, these factories ensure that builders can construct safe, durable, and aesthetically pleasing structures. As the industry continues to evolve, formwork engineering will undoubtedly play a pivotal role in shaping the future of construction, reinforcing the importance of ongoing investment in technology and sustainable practices.

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025