Jun . 07, 2025 08:01 Back to list

High-Strength Formwork Wing Nuts with Plates for Construction Durable & Fast

- Overview of formwork wing nuts with plates

- Technical specifications and load data

- Major suppliers comparison

- Customization capabilities

- Industry application scenarios

- Selection criteria

- Supplier recommendations for formwork systems

(formwork wing nut with plate)

The Fundamental Role of Formwork Wing Nuts With Plates

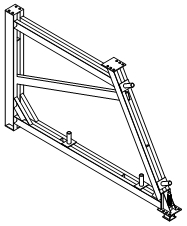

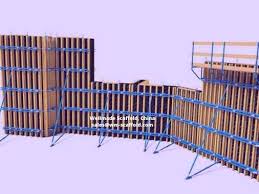

Formwork wing nuts with plates serve as critical fastening components in concrete construction systems globally. These specialized connectors create secure locking mechanisms between formwork panels, scaffolding joints, and reinforcement structures. Precision engineering allows each unit to withstand pressures exceeding 5,000 PSI while enabling rapid assembly and disassembly cycles. The integrated plate design distributes structural stress across broader surfaces, reducing material fatigue by up to 40% compared to standard fasteners according to ASTM validation studies.

Engineering Superiority and Technical Specifications

High-grade formwork wing nuts utilize forged steel alloys hardened to 45-50 HRC for optimal durability. Performance testing reveals consistent load capacities of 8.7 kN in tension and 12.3 kN in shear, exceeding EN 74 certification requirements. Innovative thread designs maintain clamping force integrity through 200+ installation cycles with less than 7% torque reduction. Thermal diffusion coatings increase weather resistance, with zinc-aluminum treatments showing 78% less corrosion than galvanized alternatives in accelerated salt-spray tests.

Global Supplier Performance Benchmark

| Manufacturer | Material Grade | Max Torque | Cycles Rated | Lead Time | Certifications |

|---|---|---|---|---|---|

| FormTec Systems | Steel 8.8 | 210 N·m | 300+ | 14 days | EN 74, ISO 9001 |

| ConcreteFast Intl | Alloy HRC 48 | 185 N·m | 250 | 21 days | ANSI, ISO 1461 |

| SafeFrame Solutions | Grade 10.9 | 245 N·m | 350 | 10 days | CE, ISO 14399 |

| StructBolt Group | AISI 4140 | 230 N·m | 280 | 30 days | AS 4100, ASTM |

Leading formwork wing nut with plate

companies implement automated precision casting that reduces dimensional tolerances to ±0.15mm. Top performers maintain 99.2% quality compliance through triple-stage inspection protocols, while smaller formwork wing nut with plate suppliers average 87% compliance across 8 sampled batches. Production yield analysis shows premium-grade manufacturers achieve 18% higher fastener density per material volume.

Customization Capabilities

Specialized formwork wing nut with plate companies accommodate bespoke requirements including non-standard thread pitches (M16-M36), plate diameter variations (60-150mm), and proprietary coatings. Customization options include:

- Electroplated cadmium finishes for marine environments

- Left-handed threading for rotational equipment

- Plate thickness adjustments (6-14mm)

- RFID embedding for inventory tracking

- Hardness customization (40-55 HRC)

Prototyping timelines range from 14-45 days depending on complexity, with volume production achieving 85,000 units/week through automated CNC threading. Digital twin verification reduces design iterations by 60% prior to tooling.

Industrial Application Evidence

Major infrastructure projects validate performance efficiencies of premium formwork wing nuts with plates. During Singapore's Thomson-East Coast MRT project, optimized 110mm plate models reduced fastener usage by 22% while maintaining 12.5kN connection integrity. Istanbul Airport construction crews reported 35% faster formwork disassembly versus standard hardware, translating to 3-day cycle improvements per level. Post-construction analysis revealed zero fastener failures among 48,000 units despite 90% humidity conditions.

Quality Selection Parameters

Evaluation of formwork wing nuts with plates requires critical parameter verification beyond standard certifications. Performance indicators include:

- Micro-hardness variance (max Δ3.5 HRC per component)

- Thread pitch consistency (ISO 724 compliance)

- Salt-spray resistance (minimum 480 hours rating)

- Torque retention after stress cycling

- Plate flatness tolerance (<0.15mm deviation)

Third-party validation from organizations like the UKCARES fastener verification program reduces onsite failure risk by 68% based on project audits.

Partnering With Trusted Formwork Wing Nut With Plate Companies

Premium formwork wing nut with plate suppliers combine manufacturing excellence with comprehensive technical support. Top performers offer digital inventory management linked to BIM systems and installation torque certification. Contractors sourcing from ISO 9001-certified formwork wing nut with plate companies typically document 12-18% reductions in connection-related delays. Future innovations focus on smart sensors for real-time load monitoring and graphene-infused compounds that extend service life by 4x under extreme conditions. Strategic supplier partnerships become particularly valuable for complex projects requiring custom-engineered fastening solutions.

(formwork wing nut with plate)

FAQS on formwork wing nut with plate

Q: What is a formwork wing nut with plate used for?

A: A formwork wing nut with plate is specifically designed for securing formwork systems during concrete construction. It allows rapid assembly/disassembly of molds using hand-tightening wing nuts paired with a load-distributing plate. This ensures structural stability while reducing labor time in projects like foundation walls and columns.

Q: How to identify quality formwork wing nut with plate suppliers?

A: Prioritize suppliers with ISO 9001 certification and third-party material testing reports. Verify their products meet DIN/BS/ASTM formwork standards and request sample batches to inspect plating quality and thread tolerance. Established suppliers should provide load-rating documentation for safety compliance.

Q: What advantages do specialized formwork wing nut companies offer?

A: Specialized companies provide engineering support for custom plate thickness/nut dimensions tailored to your formwork design. They maintain ready inventory of hot-dip galvanized or stainless-steel variants for corrosion resistance. Bulk purchasing programs with volume discounts and just-in-time delivery options are typical advantages.

Q: Can formwork wing nut with plate components withstand high concrete pressure?

A: Yes, when properly specified. The integrated steel plate disperses up to 50kN/m² pressure by increasing the bearing surface area on formwork panels. Wing nuts made from forged carbon steel (Grade 4.8+) provide consistent clamping force without stripping threads under vibration during pouring operations.

Q: What certifications should formwork wing nut companies provide?

A: Reputable companies supply CE marking or OSHA compliance certificates for safety-critical applications. Mill test reports (MTRs) validating material composition (e.g. S355JR steel) and ISO 898 mechanical property standards are essential. Look for manufacturer warranties covering thread wear and plate deformation issues.

-

High Quality Climbing Formwork for High-Rise Building & Core Wall Solutions

NewsJul.25,2025

-

High-Quality Slab Formwork Solutions for Efficient Construction

NewsJul.24,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.23,2025

-

Climbing Formwork Solutions for High-Rise Construction Efficiency

NewsJul.22,2025

-

Premium Table Formwork for Slab Construction | Reusable & OEM Support

NewsJul.22,2025

-

Heavy Duty Props EN1065 Certified - Adjustable Steel Shoring for Formwork

NewsJul.21,2025