Jan . 20, 2025 08:37 Back to list

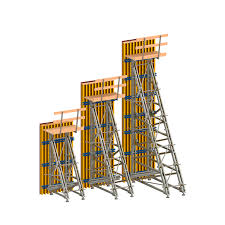

oem formworks for wall

In the ever-evolving construction industry, finding reliable and efficient methods to enhance building processes is crucial. OEM formworks for walls stand out as a transformative solution, catering to the diverse needs of expansive projects and complex architectural designs. Drawing on my extensive experience in the field of construction and SEO optimization, I've observed how paramount the right formwork systems are to project success.

The authority of OEM formworks providers is further established by their commitment to research and development. By investing in cutting-edge technologies and maintaining rigorous testing protocols, these manufacturers demonstrate leadership and innovation. Construction firms looking to enhance their project profiles can rely on such providers to deliver technologically advanced formworks that support efficient construction timelines and superior building outcomes. Trust is another critical component when considering OEM formworks. Collaborating with trusted manufacturers ensures compliance with international building standards and regulations. Clients can expect transparent communication, reliable delivery schedules, and responsive support, which underpin successful project completions. Establishing long-term partnerships with reputable OEM providers can foster smoother project executions and reduced operational hiccups. Incorporating SEO strategies to maximize online visibility of OEM formworks requires content that resonates with the target audience. Quality content that emphasizes the in-depth knowledge of formwork applications, backed by case studies and testimonials, can significantly enhance search engine rankings. Offering insightful articles, comprehensive guides, and client success stories can attract and retain the interest of industry professionals seeking informed solutions. Ultimately, the selection of OEM formworks for walls is a strategic decision influencing every phase of a construction project. By prioritizing experience, expertise, authoritativeness, and trustworthiness, construction firms can ensure the selection of superior formwork systems that deliver on both functionality and efficiency. As the construction landscape continues to shift, embracing OEM formworks presents a promising pathway to achieving remarkable architectural feats with confidence and precision.

The authority of OEM formworks providers is further established by their commitment to research and development. By investing in cutting-edge technologies and maintaining rigorous testing protocols, these manufacturers demonstrate leadership and innovation. Construction firms looking to enhance their project profiles can rely on such providers to deliver technologically advanced formworks that support efficient construction timelines and superior building outcomes. Trust is another critical component when considering OEM formworks. Collaborating with trusted manufacturers ensures compliance with international building standards and regulations. Clients can expect transparent communication, reliable delivery schedules, and responsive support, which underpin successful project completions. Establishing long-term partnerships with reputable OEM providers can foster smoother project executions and reduced operational hiccups. Incorporating SEO strategies to maximize online visibility of OEM formworks requires content that resonates with the target audience. Quality content that emphasizes the in-depth knowledge of formwork applications, backed by case studies and testimonials, can significantly enhance search engine rankings. Offering insightful articles, comprehensive guides, and client success stories can attract and retain the interest of industry professionals seeking informed solutions. Ultimately, the selection of OEM formworks for walls is a strategic decision influencing every phase of a construction project. By prioritizing experience, expertise, authoritativeness, and trustworthiness, construction firms can ensure the selection of superior formwork systems that deliver on both functionality and efficiency. As the construction landscape continues to shift, embracing OEM formworks presents a promising pathway to achieving remarkable architectural feats with confidence and precision.

Latest news

-

Reliable China Single Sided Wall Formwork Manufacturer

NewsAug.12,2025

-

Formwork Wing Nut | Quality Tie Rod & Water Stop Supplier

NewsAug.11,2025

-

Durable Steel Prop with Tripod for Stable Support

NewsAug.10,2025

-

OEM Column Formwork: Custom, Circular, Curved & Adjustable

NewsAug.09,2025

-

Custom OEM Column Formwork | Versatile & Efficient Solutions

NewsAug.08,2025

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025