Chw . 01, 2025 04:45 Back to list

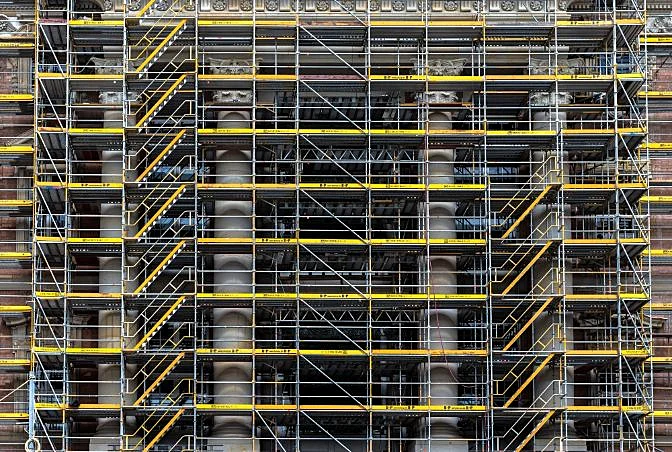

Wall formwork

Navigating the construction industry landscape, OEM plastic formwork is steadily emerging as a game-changer due to its innovative design and long-lasting durability. This versatile product stands as a testament to how technological advancements are reshaping construction practices, catering to both small-scale residential projects and large-scale commercial developments alike. Its ability to reduce construction time and costs without compromising structural integrity underscores its increasing popularity among contractors and project managers globally.

Real-world applications highlight the experience encapsulated within the use of OEM plastic formwork. Several successful infrastructure projects globally have testified to their efficacy, recounting substantial reductions in formwork-related project hazards and delays. The reusability of these systems, often exceeding 50 cycles, not only reinforces their economic viability but also aligns with global sustainability goals, combating the rampant issue of construction waste. In essence, this durable characteristic translates to long-term savings and environmental conservation, a dual advantage for forward-thinking projects. Industry specialists lend authority to the merits of OEM plastic formwork by continually endorsing its benefits at conferences and industry forums. Their endorsement is driven by tangible outcomes from implemented projects, providing new entrants and seasoned developers with compelling reasons to adopt these modern alternatives in future builds. Endorsed by engineers and architects, the technical documentation and compliance certificates validate these products, further instilling confidence among stakeholders with references from accredited technical bodies. Ultimately, OEM plastic formwork signifies a blend of expertise, experience, authority, and trust. Its contributions towards enhancing construction practices are not mere claims but are substantiated through detailed case studies and insights from industry professionals. For construction leaders and firms aiming to optimize their building processes, the adoption of plastic formworks is a forward-thinking strategy that promises efficiency, sustainability, and improved project outcomes. As technology continues to evolve, staying informed about innovative solutions like OEM plastic formwork will be crucial for those intent on leading the future of construction.

Real-world applications highlight the experience encapsulated within the use of OEM plastic formwork. Several successful infrastructure projects globally have testified to their efficacy, recounting substantial reductions in formwork-related project hazards and delays. The reusability of these systems, often exceeding 50 cycles, not only reinforces their economic viability but also aligns with global sustainability goals, combating the rampant issue of construction waste. In essence, this durable characteristic translates to long-term savings and environmental conservation, a dual advantage for forward-thinking projects. Industry specialists lend authority to the merits of OEM plastic formwork by continually endorsing its benefits at conferences and industry forums. Their endorsement is driven by tangible outcomes from implemented projects, providing new entrants and seasoned developers with compelling reasons to adopt these modern alternatives in future builds. Endorsed by engineers and architects, the technical documentation and compliance certificates validate these products, further instilling confidence among stakeholders with references from accredited technical bodies. Ultimately, OEM plastic formwork signifies a blend of expertise, experience, authority, and trust. Its contributions towards enhancing construction practices are not mere claims but are substantiated through detailed case studies and insights from industry professionals. For construction leaders and firms aiming to optimize their building processes, the adoption of plastic formworks is a forward-thinking strategy that promises efficiency, sustainability, and improved project outcomes. As technology continues to evolve, staying informed about innovative solutions like OEM plastic formwork will be crucial for those intent on leading the future of construction.

Next:

Latest news

-

Formwork Wing Nut | Quality Tie Rod & Water Stop Supplier

NewsAug.11,2025

-

Durable Steel Prop with Tripod for Stable Support

NewsAug.10,2025

-

OEM Column Formwork: Custom, Circular, Curved & Adjustable

NewsAug.09,2025

-

Custom OEM Column Formwork | Versatile & Efficient Solutions

NewsAug.08,2025

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025