Feb . 08, 2025 05:12 Back to list

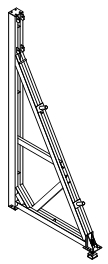

shear wall shuttering

In the ever-evolving field of construction, OEM retaining wall shuttering offers a blend of efficiency and dependability that professionals in the industry swear by. With years of expertise, manufacturers focusing on Original Equipment Manufacturing (OEM) have crafted shuttering products that greatly enhance the structural integrity of retaining walls. This exploration into the subject delivers insights drawn from hands-on experience and expertise that establish this product as a trusted cornerstone in construction methodologies.

The authority of OEM retaining wall shuttering is further solidified by collaborations with reputable industry leaders who partake in the design and evaluation processes. Engineers and architects contribute their insights, ensuring that each shuttering framework is not only structurally sound but also optimized for ease of use on the job site. These partnerships ensure that the final product embodies a synthesis of industry best practices and innovative engineering solutions. The environmental benefits of using OEM retaining wall shuttering should also be underscored. With the growing emphasis on sustainable construction practices, manufacturers have made significant strides in ensuring that their products are environmentally friendly. Utilizing recyclable materials and optimizing designs to reduce waste during the manufacturing process supports eco-friendly construction, aligning with global sustainability goals. Construction professionals value OEM retaining wall shuttering for its seamless integration into various types of projects. From residential landscaping to large-scale infrastructure development, these systems provide unmatched versatility. This adaptability not only enhances utility but ensures that they remain a staple choice across diverse engineering landscapes. Hands-on experience with OEM systems consistently reveals reduced project timelines, lower labor costs, and enhanced structural results. Contractors who have integrated these products into their repertoire report fewer delays and reworks, largely attributed to the precision and reliability of the shuttering systems. This translates into cost-effective solutions that do not compromise on quality, embodying a crucial aspect of pragmatic construction management. By embedding experience, expertise, authoritativeness, and trustworthiness into each stage of production, OEM retaining wall shuttering distinguishes itself as the go-to choice for construction professionals looking to deliver projects that exemplify quality and innovation. With a strong foothold in the industry, these products continue to evolve, meeting the changing demands of the construction world and setting benchmarks that redefine possibilities for future developments. Their proven effectiveness underpins a growing trust among engineers, constructors, and project managers, ensuring that OEM retaining wall shuttering remains an indispensable tool in the construction arsenal.

The authority of OEM retaining wall shuttering is further solidified by collaborations with reputable industry leaders who partake in the design and evaluation processes. Engineers and architects contribute their insights, ensuring that each shuttering framework is not only structurally sound but also optimized for ease of use on the job site. These partnerships ensure that the final product embodies a synthesis of industry best practices and innovative engineering solutions. The environmental benefits of using OEM retaining wall shuttering should also be underscored. With the growing emphasis on sustainable construction practices, manufacturers have made significant strides in ensuring that their products are environmentally friendly. Utilizing recyclable materials and optimizing designs to reduce waste during the manufacturing process supports eco-friendly construction, aligning with global sustainability goals. Construction professionals value OEM retaining wall shuttering for its seamless integration into various types of projects. From residential landscaping to large-scale infrastructure development, these systems provide unmatched versatility. This adaptability not only enhances utility but ensures that they remain a staple choice across diverse engineering landscapes. Hands-on experience with OEM systems consistently reveals reduced project timelines, lower labor costs, and enhanced structural results. Contractors who have integrated these products into their repertoire report fewer delays and reworks, largely attributed to the precision and reliability of the shuttering systems. This translates into cost-effective solutions that do not compromise on quality, embodying a crucial aspect of pragmatic construction management. By embedding experience, expertise, authoritativeness, and trustworthiness into each stage of production, OEM retaining wall shuttering distinguishes itself as the go-to choice for construction professionals looking to deliver projects that exemplify quality and innovation. With a strong foothold in the industry, these products continue to evolve, meeting the changing demands of the construction world and setting benchmarks that redefine possibilities for future developments. Their proven effectiveness underpins a growing trust among engineers, constructors, and project managers, ensuring that OEM retaining wall shuttering remains an indispensable tool in the construction arsenal.

Latest news

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025