feb . 12, 2025 13:53 Back to list

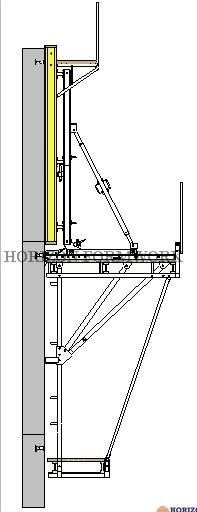

Climbing Formwork CB240

Navigating the world of OEM walk through scaffolding requires both expertise and keen attention to industry standards to ensure safety, efficiency, and the highest quality results. Walk through scaffolding, an essential component in the construction and maintenance sectors, offers a range of benefits from versatility in demanding environments to enhanced productivity on-site. As an authoritative voice in the realm of OEM walk through scaffolding, I aim to guide you through this specialized field, emphasizing industry best practices, innovative trends, and the critical factors influencing purchasing decisions.

Authoritativeness in the industry can be gauged through a provider’s track record. A reputable OEM provider should have a history of successful projects across different sectors such as construction, oil and gas, and transportation infrastructure. Furthermore, they should offer comprehensive training programs, equipping workers with necessary skills and knowledge to erect and dismantle scaffolds safely and efficiently. Real-world case studies and testimonials from industry leaders serve as powerful endorsements, cementing trust in a provider’s capabilities. Trust is paramount when selecting an OEM walk through scaffolding provider. Transparency in the manufacturing process, adherence to strict quality control measures, and ongoing product development reflect a company’s commitment to trustworthiness. Providers that take responsibility through warranties and after-sales services demonstrate a strong dedication to customer satisfaction, pivotal in fostering long-term relationships. Moreover, it’s crucial for buyers to ensure that their providers are proactive in staying aligned with the latest technological advancements and industry trends, showcasing a company’s forward-thinking approach and readiness to adapt to future challenges. To optimize productivity and safety, innovation plays a significant role. Cutting-edge advancements in scaffolding design, such as modular systems and advanced locking mechanisms, are reshaping the landscape, allowing for quicker assembly times and increased safety on-site. As digital transformation permeates the construction industry, some pioneering OEM providers have begun integrating smart technology into their scaffolding systems. Features such as IoT sensors can monitor the structural integrity and environmental conditions in real-time, alerting workers of potential hazards and ensuring maintenance is conducted promptly. In conclusion, the world of OEM walk through scaffolding is richly steeped in experience, expertise, authoritativeness, and trustworthiness. Whether you’re a project manager, site supervisor, or facility owner, selecting the right scaffolding system hinges on these four pillars. By partnering with an experienced and reputable OEM provider, you can rest assured that your investment will yield safety, quality, and efficiency, driving your projects to success. As the landscape continues to evolve with technological innovations and safety improvements, staying informed and adaptable remains essential. Such commitment to excellence not only enhances operational effectiveness but also contributes to creating safer, more sustainable workplaces worldwide.

Authoritativeness in the industry can be gauged through a provider’s track record. A reputable OEM provider should have a history of successful projects across different sectors such as construction, oil and gas, and transportation infrastructure. Furthermore, they should offer comprehensive training programs, equipping workers with necessary skills and knowledge to erect and dismantle scaffolds safely and efficiently. Real-world case studies and testimonials from industry leaders serve as powerful endorsements, cementing trust in a provider’s capabilities. Trust is paramount when selecting an OEM walk through scaffolding provider. Transparency in the manufacturing process, adherence to strict quality control measures, and ongoing product development reflect a company’s commitment to trustworthiness. Providers that take responsibility through warranties and after-sales services demonstrate a strong dedication to customer satisfaction, pivotal in fostering long-term relationships. Moreover, it’s crucial for buyers to ensure that their providers are proactive in staying aligned with the latest technological advancements and industry trends, showcasing a company’s forward-thinking approach and readiness to adapt to future challenges. To optimize productivity and safety, innovation plays a significant role. Cutting-edge advancements in scaffolding design, such as modular systems and advanced locking mechanisms, are reshaping the landscape, allowing for quicker assembly times and increased safety on-site. As digital transformation permeates the construction industry, some pioneering OEM providers have begun integrating smart technology into their scaffolding systems. Features such as IoT sensors can monitor the structural integrity and environmental conditions in real-time, alerting workers of potential hazards and ensuring maintenance is conducted promptly. In conclusion, the world of OEM walk through scaffolding is richly steeped in experience, expertise, authoritativeness, and trustworthiness. Whether you’re a project manager, site supervisor, or facility owner, selecting the right scaffolding system hinges on these four pillars. By partnering with an experienced and reputable OEM provider, you can rest assured that your investment will yield safety, quality, and efficiency, driving your projects to success. As the landscape continues to evolve with technological innovations and safety improvements, staying informed and adaptable remains essential. Such commitment to excellence not only enhances operational effectiveness but also contributes to creating safer, more sustainable workplaces worldwide.

Next:

Latest news

-

Durable Steel Prop with Tripod for Stable Support

NewsAug.10,2025

-

OEM Column Formwork: Custom, Circular, Curved & Adjustable

NewsAug.09,2025

-

Custom OEM Column Formwork | Versatile & Efficient Solutions

NewsAug.08,2025

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025