Sau . 24, 2025 04:07 Back to list

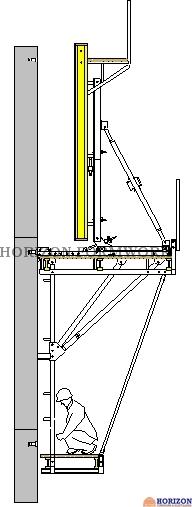

oem climb scaffolding

Purchasing metal scaffolding is crucial for construction companies, event organizers, and industries that frequently deal with high-rise tasks. Selecting the right OEM metal scaffolding can make a difference in terms of safety, efficiency, and cost-effectiveness, but understanding the pricing can be quite intricate. By comprehending the factors affecting the OEM metal scaffolding price, companies can make informed decisions that align with their operational and financial goals.

Market Demand and Economic Conditions Fluctuations in the construction industry directly impact scaffolding prices. During times of increased construction activity or when large-scale projects are underway, demand spikes can lead to higher prices. Conversely, economic downturns might see a surplus of scaffolding products, potentially driving prices down. Supply Chain Dynamics The logistics involved in obtaining materials and delivering finished scaffolding to the end-user also play a role. Disruptions like supplier shortages or increased transportation costs can escalate prices. Companies can mitigate this by developing strategic partnerships with reliable OEM providers that have resilient supply chain networks. Lifecycle Costs An often-overlooked aspect is the lifecycle cost of the scaffolding. While initial costs are a critical factor, maintenance, repair, and eventual replacement costs should also be considered. Investing in higher-quality scaffolding may reduce total lifecycle costs through decreased need for repairs and longer useful life. Environmental Impact With growing emphasis on sustainability, eco-friendly scaffolding options, though potentially more expensive, are gaining traction. Materials that are recyclable or manufacturing processes that reduce carbon emissions appeal to environmentally conscious buyers and align with corporate social responsibility goals. In conclusion, navigating the pricing of OEM metal scaffolding requires a balanced approach, examining both immediate and long-term implications of the purchase. By leveraging expertise in procurement, and understanding the nuances of quality, compliance, and market conditions, companies can make strategic decisions. These decisions not only facilitate successful projects but also contribute to an organization's overarching financial health and operational reliability. Investing wisely in scaffolding is not just about the immediate transaction—it’s about building a foundation for sustainable growth.

Market Demand and Economic Conditions Fluctuations in the construction industry directly impact scaffolding prices. During times of increased construction activity or when large-scale projects are underway, demand spikes can lead to higher prices. Conversely, economic downturns might see a surplus of scaffolding products, potentially driving prices down. Supply Chain Dynamics The logistics involved in obtaining materials and delivering finished scaffolding to the end-user also play a role. Disruptions like supplier shortages or increased transportation costs can escalate prices. Companies can mitigate this by developing strategic partnerships with reliable OEM providers that have resilient supply chain networks. Lifecycle Costs An often-overlooked aspect is the lifecycle cost of the scaffolding. While initial costs are a critical factor, maintenance, repair, and eventual replacement costs should also be considered. Investing in higher-quality scaffolding may reduce total lifecycle costs through decreased need for repairs and longer useful life. Environmental Impact With growing emphasis on sustainability, eco-friendly scaffolding options, though potentially more expensive, are gaining traction. Materials that are recyclable or manufacturing processes that reduce carbon emissions appeal to environmentally conscious buyers and align with corporate social responsibility goals. In conclusion, navigating the pricing of OEM metal scaffolding requires a balanced approach, examining both immediate and long-term implications of the purchase. By leveraging expertise in procurement, and understanding the nuances of quality, compliance, and market conditions, companies can make strategic decisions. These decisions not only facilitate successful projects but also contribute to an organization's overarching financial health and operational reliability. Investing wisely in scaffolding is not just about the immediate transaction—it’s about building a foundation for sustainable growth.

Next:

Latest news

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025