feb. . 08, 2025 08:09 Back to list

Wall formwork

Choosing the right formwork can make a significant difference in the quality and durability of construction projects, especially when dealing with challenging weather conditions. An oem waterproof formwork can be an excellent choice for many construction businesses looking to enhance their efficiency and reliability.

Trustworthiness in construction is paramount — both in terms of safety and reliability. Using substandard materials can lead to disastrous outcomes, but OEM waterproof formwork offers reassurance to contractors and end-users alike. Manufacturers usually back these products with detailed warranty agreements, reflecting their confidence in the product's longevity and performance. Such warranties offer peace of mind to contractors, knowing that any formwork failures from manufacturing defects will be rectified. Moreover, using reputable, certified waterproof formwork supports compliance with regional and international building codes, ensuring structures are built to recognized safety standards. Incorporating practical experiences from industry veterans can further substantiate the benefits of OEM waterproof formwork. Many top-tier construction companies have transitioned to using these advanced materials and report marked improvements in worksite efficiency. For example, tasks such as setting up and dismantling formwork are streamlined due to the lightweight yet sturdy nature of these products. Workers encounter less physical strain, reducing the risk of onsite injuries, while speeding up the timeline of project phases. Furthermore, the ability to withstand unplanned exposure to water without delay extends well into post-construction maintenance. In scenarios where water intrusion could compromise the integrity of structural components, waterproof formworks offer a robust line of defense. Structures such as dams, bridges, and waterfront constructions especially reap these benefits, ensuring that the investment into premium formwork results in reduced long-term maintenance costs. Ultimately, when choosing construction materials, it's crucial to prioritize not just initial cost savings but also the overall value. OEM waterproof formwork provides a compelling blend of durability, efficiency, and environmental responsibility, meeting contemporary construction challenges head-on. Entities that make the switch to this innovative technology position themselves not just for immediate project success, but for continued relevance and competitiveness in a rapidly evolving industry landscape.

Trustworthiness in construction is paramount — both in terms of safety and reliability. Using substandard materials can lead to disastrous outcomes, but OEM waterproof formwork offers reassurance to contractors and end-users alike. Manufacturers usually back these products with detailed warranty agreements, reflecting their confidence in the product's longevity and performance. Such warranties offer peace of mind to contractors, knowing that any formwork failures from manufacturing defects will be rectified. Moreover, using reputable, certified waterproof formwork supports compliance with regional and international building codes, ensuring structures are built to recognized safety standards. Incorporating practical experiences from industry veterans can further substantiate the benefits of OEM waterproof formwork. Many top-tier construction companies have transitioned to using these advanced materials and report marked improvements in worksite efficiency. For example, tasks such as setting up and dismantling formwork are streamlined due to the lightweight yet sturdy nature of these products. Workers encounter less physical strain, reducing the risk of onsite injuries, while speeding up the timeline of project phases. Furthermore, the ability to withstand unplanned exposure to water without delay extends well into post-construction maintenance. In scenarios where water intrusion could compromise the integrity of structural components, waterproof formworks offer a robust line of defense. Structures such as dams, bridges, and waterfront constructions especially reap these benefits, ensuring that the investment into premium formwork results in reduced long-term maintenance costs. Ultimately, when choosing construction materials, it's crucial to prioritize not just initial cost savings but also the overall value. OEM waterproof formwork provides a compelling blend of durability, efficiency, and environmental responsibility, meeting contemporary construction challenges head-on. Entities that make the switch to this innovative technology position themselves not just for immediate project success, but for continued relevance and competitiveness in a rapidly evolving industry landscape.

Latest news

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

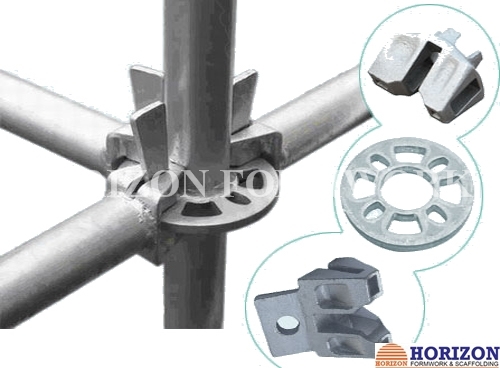

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025