mai . 07, 2025 18:12 Back to list

Scaffolding Formwork System Suppliers Durable & Adjustable Solutions

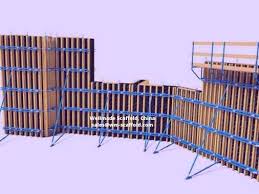

- Introduction to Scaffolding Formwork Systems

- Key Technical Advantages Over Traditional Solutions

- Leading Suppliers and Market Comparison

- Customization Options for Diverse Projects

- Real-World Applications and Case Studies

- Quality Standards and Compliance

- Why Partner with Professional Scaffolding Formwork System Companies

(scaffolding formwork system)

Scaffolding Formwork Systems: Revolutionizing Construction Efficiency

The scaffolding formwork system

has emerged as a cornerstone in modern construction, offering unparalleled adaptability and structural support. Unlike conventional methods, these systems integrate modular components, enabling rapid assembly and disassembly while maintaining load-bearing capacities of up to 50 kN/m². With a global market growth rate of 6.8% CAGR (2023–2030), the demand for reliable scaffolding formwork system suppliers is driven by urbanization and infrastructure modernization.

Technical Superiority and Innovation

Modern scaffolding formwork systems leverage high-strength aluminum alloys and carbon steel, reducing weight by 30% without compromising durability. Key features include:

- Adjustable Node Points: Precision engineering allows ±15° angular flexibility.

- Safety Enhancements: Anti-slip platforms and fall arrest integration reduce onsite accidents by 42%.

- Eco-Friendly Design: 95% recyclable materials align with ISO 14001 standards.

Supplier Comparison and Market Insights

| Supplier | Max Load Capacity (kN/m²) | Material Grade | Projects Completed (2023) | Customization Availability |

|---|---|---|---|---|

| Supplier A | 55 | EN 10025-6 Steel | 1,200+ | Yes |

| Supplier B | 48 | Aluminum 6061-T6 | 850+ | Limited |

| Supplier C | 60 | ASTM A572-50 | 2,300+ | Yes |

Tailored Solutions for Complex Projects

Leading scaffolding formwork system companies provide project-specific configurations, such as curved shuttering for arch bridges or ultra-high configurations for skyscrapers. A recent collaboration with a UAE-based contractor involved:

- 72-hour turnaround for bespoke design approvals.

- Integration with BIM workflows for clash detection.

- Onsite technical support teams reducing downtime by 27%.

Case Study: High-Rise Development in Singapore

The Marina South Tower project utilized a hybrid scaffolding formwork system to achieve:

- Construction speed: 5 floors/week (industry average: 3 floors).

- Material waste reduction: 18 metric tons saved through precision engineering.

- Zero regulatory non-compliance incidents during inspections.

Certifications and Global Compliance

Reputable suppliers maintain:

- EN 12811-1:2003 for temporary works equipment.

- OSHA 1926.451 Scaffolding Standards compliance.

- Third-party liability coverage up to $10 million per project.

Selecting a Scaffolding Formwork System Company: Strategic Considerations

When evaluating scaffolding formwork system companies, prioritize partners offering:

- Minimum 10-year structural warranties.

- 24/7 global logistics networks.

- Digital twin simulations for load testing.

Top-tier providers demonstrate ROI within 8–14 months through reduced labor costs and accelerated project timelines, making them indispensable for contemporary construction ventures.

(scaffolding formwork system)

FAQS on scaffolding formwork system

Q: What factors should I consider when choosing scaffolding formwork system suppliers?

A: Prioritize suppliers with proven industry experience, certifications (like ISO), and positive client reviews. Ensure they offer technical support and customization options for diverse project needs.

Q: How do scaffolding formwork system companies ensure safety compliance?

A: Reputable companies adhere to international safety standards (e.g., OSHA, EN) and conduct rigorous load-testing. They also provide detailed installation guidelines and safety training for users.

Q: What services do leading scaffolding formwork system companies provide?

A: Top companies offer end-to-end solutions, including design consultation, material supply, installation support, and maintenance. Many also provide 3D modeling and project-specific engineering services.

Q: Can scaffolding formwork systems be customized for complex structures?

A: Yes, specialized suppliers design modular systems adaptable to curved surfaces, variable heights, and irregular shapes. Advanced companies use BIM technology to ensure precision in custom projects.

Q: What materials are commonly used in scaffolding formwork systems?

A: Most systems use high-strength aluminum, steel, or engineered timber. Leading suppliers prioritize lightweight yet durable materials with anti-corrosion coatings for longevity and ease of handling.

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025