Jan . 30, 2025 05:15 Back to list

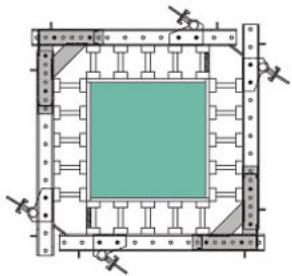

Column formwork

Navigating the landscape of construction tools, one cannot overlook the pivotal role that OEM column shuttering plays. This product underscores an evolution, reflecting expert design, reliable functionality, and tailored solutions to meet modern construction needs. Comprehending the nuances of OEM column shuttering is fundamental for builders and engineers aspiring to optimize construction efficiency while maintaining structural integrity.

Trustworthiness is a critical component when selecting column shuttering, and OEM manufacturers often prioritize rigorous quality control and adherence to safety standards. This commitment to quality translates into reliable products that receive certifications from various constructing regulating bodies. Engineers and project managers can rest assured that these products have undergone extensive testing, proving their capability to perform under real-world conditions. Moreover, the environmental impact of construction activities is gaining more focus, and OEM column shuttering manufacturers are at the forefront of developing sustainable practices. Many have adopted environmentally friendly materials and production processes, reducing waste and energy consumption. This shift not only improves the environmental footprint of projects but also aligns with global initiatives aimed at promoting sustainability in all sectors. Field experience also suggests that collaboration between construction teams and OEM manufacturers can foster innovative solutions, tailoring products to fit challenging project needs. Such partnerships enable on-site assessments and iterative designs, ensuring that the column shuttering meets the exact requirements of the job. These collaborative efforts extend beyond just the initial phase, often including ongoing support throughout the project's lifecycle, enhancing adaptability and resource allocation. In conclusion, OEM column shuttering offers a sophisticated, reliable, and environmentally conscious option for construction professionals. Its ability to provide tailored solutions backed by expertise and rigorous testing embodies a benchmark for construction efficiency. As projects continue to grow in complexity and scope, embracing these advanced shuttering systems becomes not just advantageous but essential for success. Builders and engineers looking to excel should consider OEM column shuttering a vital tool in their arsenal, confident in its ability to support structures of integrity and longevity.

Trustworthiness is a critical component when selecting column shuttering, and OEM manufacturers often prioritize rigorous quality control and adherence to safety standards. This commitment to quality translates into reliable products that receive certifications from various constructing regulating bodies. Engineers and project managers can rest assured that these products have undergone extensive testing, proving their capability to perform under real-world conditions. Moreover, the environmental impact of construction activities is gaining more focus, and OEM column shuttering manufacturers are at the forefront of developing sustainable practices. Many have adopted environmentally friendly materials and production processes, reducing waste and energy consumption. This shift not only improves the environmental footprint of projects but also aligns with global initiatives aimed at promoting sustainability in all sectors. Field experience also suggests that collaboration between construction teams and OEM manufacturers can foster innovative solutions, tailoring products to fit challenging project needs. Such partnerships enable on-site assessments and iterative designs, ensuring that the column shuttering meets the exact requirements of the job. These collaborative efforts extend beyond just the initial phase, often including ongoing support throughout the project's lifecycle, enhancing adaptability and resource allocation. In conclusion, OEM column shuttering offers a sophisticated, reliable, and environmentally conscious option for construction professionals. Its ability to provide tailored solutions backed by expertise and rigorous testing embodies a benchmark for construction efficiency. As projects continue to grow in complexity and scope, embracing these advanced shuttering systems becomes not just advantageous but essential for success. Builders and engineers looking to excel should consider OEM column shuttering a vital tool in their arsenal, confident in its ability to support structures of integrity and longevity.

Next:

Latest news

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025