jan . 20, 2025 03:46 Back to list

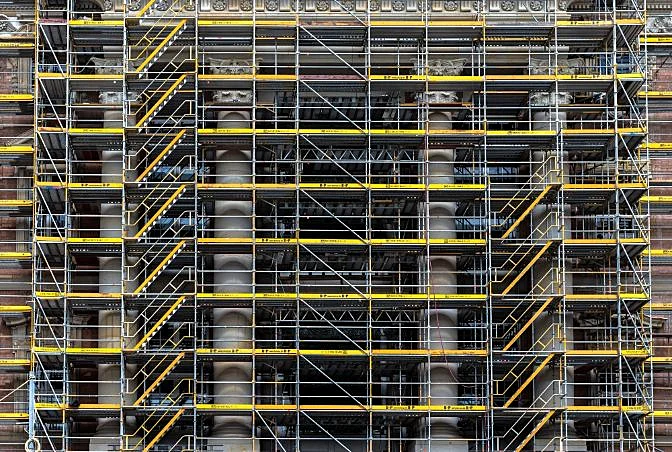

Shoring prop-Light Duty

In the ever-evolving world of construction, the demand for innovative and customizable solutions is paramount. One such remarkable product that caters to this demand is the OEM adjustable shoring prop. This underappreciated tool is critical in maintaining safety and efficiency on construction sites across the globe.

Trustworthiness in construction tools and materials cannot be overstated. The collapses of improperly supported structures can lead to catastrophic consequences, hence the pressing necessity for dependable equipment. Contractors who have implemented OEM adjustable shoring props in their projects consistently report enhanced safety and efficiency. The capability to easily adjust the height and angle of the props means that laborers can swiftly and correctly set up support systems, reducing the time spent in potentially hazardous situations. Moreover, OEM adjustable shoring props are crafted using high-grade materials such as reinforced steel or aluminum, which combine strength with lightweight properties. This ensures that, while the props are easy to handle and transport, they do not compromise on durability and performance. Whether used to support a slab, hold up a temporary roof, or stabilize a wall under construction, these props exhibit minimal wear and tear, offering enduring service life and a sound return on investment. Real experiences from the field highlight the benefits of these adaptable props. Construction teams have noted significant improvements in project timelines due to the reduced complexity in setting up and adjusting support equipment. The reliability of OEM adjustable shoring props translates directly to fewer interruptions, less downtime, and better overall productivity. As the construction industry continues to embrace more sustainable and efficient practices, the role of OEM adjustable shoring props becomes even more significant. These props are not merely tools; they are an integral part of the construction process, driving forward innovation and effectiveness. In conclusion, OEM adjustable shoring props represent a fusion of engineering expertise and practical application that meets the diverse needs of modern construction projects. Their customization options, rigorous testing, and durable build offer unmatched support, safety, and flexibility for any project, making them an essential investment for construction firms aiming to uphold the highest standards of structural integrity and project efficiency.

Trustworthiness in construction tools and materials cannot be overstated. The collapses of improperly supported structures can lead to catastrophic consequences, hence the pressing necessity for dependable equipment. Contractors who have implemented OEM adjustable shoring props in their projects consistently report enhanced safety and efficiency. The capability to easily adjust the height and angle of the props means that laborers can swiftly and correctly set up support systems, reducing the time spent in potentially hazardous situations. Moreover, OEM adjustable shoring props are crafted using high-grade materials such as reinforced steel or aluminum, which combine strength with lightweight properties. This ensures that, while the props are easy to handle and transport, they do not compromise on durability and performance. Whether used to support a slab, hold up a temporary roof, or stabilize a wall under construction, these props exhibit minimal wear and tear, offering enduring service life and a sound return on investment. Real experiences from the field highlight the benefits of these adaptable props. Construction teams have noted significant improvements in project timelines due to the reduced complexity in setting up and adjusting support equipment. The reliability of OEM adjustable shoring props translates directly to fewer interruptions, less downtime, and better overall productivity. As the construction industry continues to embrace more sustainable and efficient practices, the role of OEM adjustable shoring props becomes even more significant. These props are not merely tools; they are an integral part of the construction process, driving forward innovation and effectiveness. In conclusion, OEM adjustable shoring props represent a fusion of engineering expertise and practical application that meets the diverse needs of modern construction projects. Their customization options, rigorous testing, and durable build offer unmatched support, safety, and flexibility for any project, making them an essential investment for construction firms aiming to uphold the highest standards of structural integrity and project efficiency.

Next:

Latest news

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025