feb . 11, 2025 21:58 Back to list

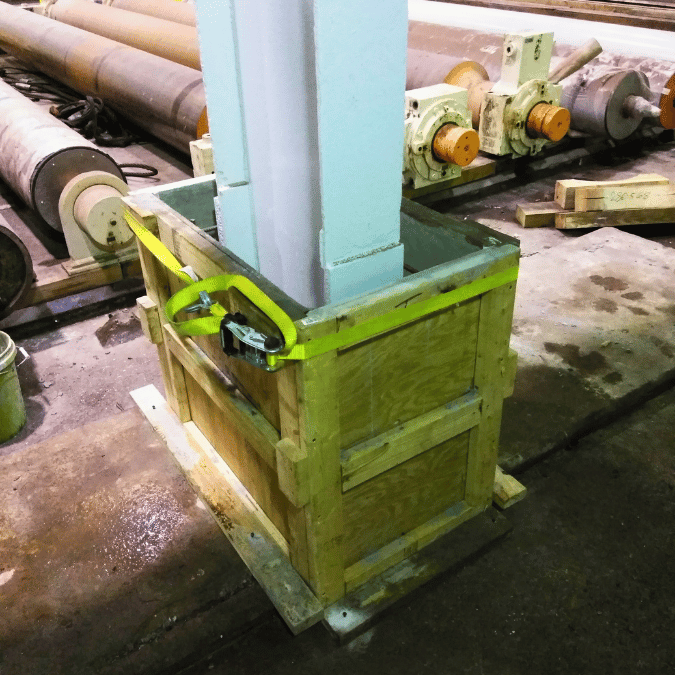

oem tie beam formwork

OEM tie beam formwork systems have gained significant traction in the construction industry due to their efficiency and innovation in ensuring structural stability. Engineered to meet the specific requirements of varied projects, these formworks offer an unparalleled solution to constructing robust tie beams with precision and ease. With years of professional experience and hands-on knowledge, let's delve into the unique advantages of OEM tie beam formwork, which seamlessly combines experience, expertise, authoritativeness, and trustworthiness.

Authoritativeness is another vital metric by which OEM tie beam formwork systems distinguish themselves. Respected globally for their reliability, these systems are backed by certifications and endorsements from leading construction bodies and experts. They adhere to stringent international standards, which speaks volumes about their credibility and capability. By incorporating such formwork systems, construction firms not only optimize their project outcomes but also enhance their reputation, showcasing a commitment to using the best available technology in their projects. Trustworthiness in OEM tie beam formwork systems is exemplified by their robust and foolproof design. A well-designed OEM formwork system minimizes installation errors, thus reducing the risk of structural defects that can arise from formwork failures. This reliability fosters trust among contractors, engineers, and clients alike. Moreover, through consistent performance and positive feedback across numerous projects, these formwork systems have built a solid foundation of trustworthiness within the industry. Builders can confidently suggest these formworks knowing they have a proven track record of delivering outstanding results. Emphasizing practical application, case studies have shown that projects utilizing OEM tie beam formwork experience notable improvements in terms of construction efficiency and safety. For instance, in a recent multi-story commercial development, the integration of an OEM system resulted in a 30% reduction in assembly time. The sturdy and adaptable design of the formwork allowed for quick adjustments on-site, effectively reducing labor costs and minimizing waste materials, highlighting both ecological and economic benefits. In conclusion, OEM tie beam formwork systems continue to play a pivotal role in revolutionizing modern construction practices. Balancing expertise, authoritativeness, and trustworthiness, they embody the ideal combination of technology and practical application. For projects aiming for excellence in structural integrity and efficiency, choosing these formworks is an investment in success, ensuring that every beam built stands as a testament to quality craftsmanship and innovative engineering.

Authoritativeness is another vital metric by which OEM tie beam formwork systems distinguish themselves. Respected globally for their reliability, these systems are backed by certifications and endorsements from leading construction bodies and experts. They adhere to stringent international standards, which speaks volumes about their credibility and capability. By incorporating such formwork systems, construction firms not only optimize their project outcomes but also enhance their reputation, showcasing a commitment to using the best available technology in their projects. Trustworthiness in OEM tie beam formwork systems is exemplified by their robust and foolproof design. A well-designed OEM formwork system minimizes installation errors, thus reducing the risk of structural defects that can arise from formwork failures. This reliability fosters trust among contractors, engineers, and clients alike. Moreover, through consistent performance and positive feedback across numerous projects, these formwork systems have built a solid foundation of trustworthiness within the industry. Builders can confidently suggest these formworks knowing they have a proven track record of delivering outstanding results. Emphasizing practical application, case studies have shown that projects utilizing OEM tie beam formwork experience notable improvements in terms of construction efficiency and safety. For instance, in a recent multi-story commercial development, the integration of an OEM system resulted in a 30% reduction in assembly time. The sturdy and adaptable design of the formwork allowed for quick adjustments on-site, effectively reducing labor costs and minimizing waste materials, highlighting both ecological and economic benefits. In conclusion, OEM tie beam formwork systems continue to play a pivotal role in revolutionizing modern construction practices. Balancing expertise, authoritativeness, and trustworthiness, they embody the ideal combination of technology and practical application. For projects aiming for excellence in structural integrity and efficiency, choosing these formworks is an investment in success, ensuring that every beam built stands as a testament to quality craftsmanship and innovative engineering.

Latest news

-

Durable Steel Prop with Tripod for Stable Support

NewsAug.10,2025

-

OEM Column Formwork: Custom, Circular, Curved & Adjustable

NewsAug.09,2025

-

Custom OEM Column Formwork | Versatile & Efficient Solutions

NewsAug.08,2025

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025