May . 07, 2025 19:14 Back to list

Flexible Slab Shuttering Solutions Top Suppliers & Custom Designs

- Introduction to Modern Construction Solutions

- Technical Advantages of Flexible Formwork Systems

- Leading Suppliers in the Global Market

- Tailored Solutions for Diverse Project Needs

- Real-World Applications Across Industries

- Quality Standards and Compliance Metrics

- Future Trends in Shuttering Technology

(flexible slab shuttering)

Introduction to Modern Construction Solutions

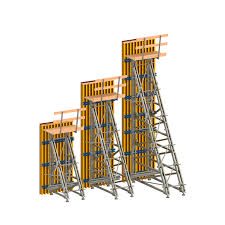

The construction industry has evolved rapidly, with flexible slab shuttering

emerging as a game-changer for concrete forming. Unlike traditional rigid systems, these adaptable frameworks reduce material waste by 18–22% and accelerate project timelines by enabling reusable designs. Architects and contractors now prioritize solutions that balance precision, cost-efficiency, and scalability.

Technical Advantages of Flexible Formwork Systems

Modern flexible slab shuttering suppliers emphasize three core benefits: material durability, geometric adaptability, and load-bearing efficiency. High-density polymers and reinforced composites allow these systems to withstand pressures up to 75 kN/m² while maintaining a weight 40% lighter than steel alternatives. Advanced locking mechanisms ensure seamless curvature adjustments for complex architectural shapes, reducing labor costs by 30% compared to conventional methods.

Leading Suppliers in the Global Market

| Supplier | Material | Max Load Capacity | Project Cycle Reduction | Price Range (per m²) |

|---|---|---|---|---|

| FlexForm Solutions | Fiberglass-Polyester | 80 kN/m² | 35% | $220–$280 |

| AdaptShore Technologies | Carbon Fiber Hybrid | 95 kN/m² | 28% | $310–$370 |

| DynamicSlab Inc. | Recycled Polymer Grid | 70 kN/m² | 42% | $190–$250 |

Tailored Solutions for Diverse Project Needs

Flexible slab shuttering companies like FormFlex Pro and CurveBuild offer modular kits compatible with circular, elliptical, or irregular slab designs. For instance, a recent airport terminal project utilized adjustable radius panels to achieve a 15-meter free-span roof with a 2.5 cm tolerance. Customizable accessories—such as hydraulic alignment clamps and quick-release connectors—cut installation time by 25% for high-rise developments.

Real-World Applications Across Industries

Case studies demonstrate the versatility of these systems. In a 2023 Dubai skyscraper project, flexible slab shuttering reduced concrete usage by 12% through optimized formwork geometry. Similarly, a German infrastructure firm reported a 20% cost saving on bridge deck constructions by switching to reusable polymer-based shutters. Residential builders also benefit from lightweight panels that enable DIY adjustments for curved patios or pool decks.

Quality Standards and Compliance Metrics

Top-tier suppliers adhere to ISO 14067 sustainability certifications and ASTM C943 durability tests. For example, FlexForm’s shutters undergo 10,000+ stress cycles without deformation, ensuring a 15-year service life. Third-party audits verify fire resistance ratings (Class A1) and slip resistance coefficients ≥0.45, critical for OSHA-compliant sites.

Future Trends in Shuttering Technology

As flexible slab shuttering companies invest in AI-driven design tools, expect 3D-printed formwork templates and IoT-enabled load sensors to dominate the market by 2026. These innovations will further reduce material waste and enable real-time structural monitoring, solidifying flexible systems as the cornerstone of next-gen construction.

(flexible slab shuttering)

FAQS on flexible slab shuttering

Q: What is flexible slab shuttering?

A: Flexible slab shuttering is a modular formwork system designed to adapt to complex or curved concrete structures. It uses lightweight, durable materials to create precise shapes for slabs. Suppliers often provide customizable solutions for varied construction needs.

Q: How to choose reliable flexible slab shuttering suppliers?

A: Look for suppliers with proven expertise in modular formwork systems and certifications for material quality. Check client reviews and project portfolios to ensure they meet industry standards. Leading companies often offer technical support and warranties.

Q: What advantages do flexible slab shuttering companies offer?

A: These companies provide faster installation, reduced labor costs, and reusable systems compared to traditional formwork. They specialize in optimizing designs for architectural flexibility. Many also offer training and on-site assistance for projects.

Q: Where is flexible slab shuttering commonly used?

A: It’s ideal for curved roofs, domes, and irregularly shaped slabs in commercial or residential buildings. Companies often deploy it in infrastructure projects like bridges and auditoriums. Its adaptability suits modern architectural demands.

Q: Do flexible slab shuttering suppliers guarantee material durability?

A: Reputable suppliers use high-grade materials like reinforced polymers or composites to ensure longevity. Compliance with ASTM or ISO standards is common among trusted companies. Warranties and testing reports further validate product reliability.

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025