Oca . 19, 2025 03:30 Back to list

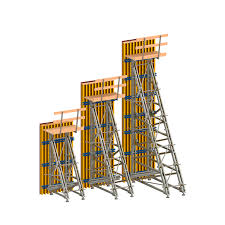

oem concrete wall formwork

Navigating the intricate landscape of OEM conventional formwork requires a blend of industry expertise, practical experience, and a keen understanding of engineering principles. Conventional formwork systems, known for their versatility and cost-effectiveness, are pivotal in constructing concrete structures such as residential buildings, commercial complexes, and infrastructure projects. As an OEM provider specializing in these systems, the emphasis on quality, precision, and reliability cannot be overstated, influencing developers’ choice when determining their construction methodologies.

Sustainability is increasingly becoming a critical consideration in the realm of conventional formwork. As environmental awareness grows, OEM providers are exploring eco-friendly materials and processes. Reusability and recyclability of formwork components are gaining traction, reducing the carbon footprint associated with construction activities. Innovative approaches, like adopting modular formwork systems, also contribute to sustainability by minimizing waste and promoting resource efficiency. The dynamic nature of construction demands that OEM providers continuously evolve, leveraging technological advancements and industry insights to stay ahead. Automation in manufacturing, the integration of IoT for monitoring formwork performance, and the application of data analytics to optimize resource allocation are areas where leading OEM providers are making strides. Furthermore, fostering partnerships with research institutions facilitates innovation and the adoption of cutting-edge technologies in formwork design and production. Exemplary OEM conventional formwork providers prioritize customer feedback, incorporating it to enhance product offerings and service delivery. By actively engaging with stakeholders across the construction ecosystem—engineers, site managers, and end-users—they gain valuable perspectives that drive continuous improvement. This customer-centric approach ensures that their products not only meet but exceed client expectations, establishing long-term loyalty and market leadership. Ultimately, the choice of conventional formwork influences the success of a construction project. It is imperative for construction professionals to partner with reputable OEM suppliers who embody experience, expertise, authoritativeness, and trustworthiness. Such partnerships not only guarantee the delivery of high-quality formwork systems but also contribute to the overall success and sustainability of construction endeavors.

Sustainability is increasingly becoming a critical consideration in the realm of conventional formwork. As environmental awareness grows, OEM providers are exploring eco-friendly materials and processes. Reusability and recyclability of formwork components are gaining traction, reducing the carbon footprint associated with construction activities. Innovative approaches, like adopting modular formwork systems, also contribute to sustainability by minimizing waste and promoting resource efficiency. The dynamic nature of construction demands that OEM providers continuously evolve, leveraging technological advancements and industry insights to stay ahead. Automation in manufacturing, the integration of IoT for monitoring formwork performance, and the application of data analytics to optimize resource allocation are areas where leading OEM providers are making strides. Furthermore, fostering partnerships with research institutions facilitates innovation and the adoption of cutting-edge technologies in formwork design and production. Exemplary OEM conventional formwork providers prioritize customer feedback, incorporating it to enhance product offerings and service delivery. By actively engaging with stakeholders across the construction ecosystem—engineers, site managers, and end-users—they gain valuable perspectives that drive continuous improvement. This customer-centric approach ensures that their products not only meet but exceed client expectations, establishing long-term loyalty and market leadership. Ultimately, the choice of conventional formwork influences the success of a construction project. It is imperative for construction professionals to partner with reputable OEM suppliers who embody experience, expertise, authoritativeness, and trustworthiness. Such partnerships not only guarantee the delivery of high-quality formwork systems but also contribute to the overall success and sustainability of construction endeavors.

Latest news

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025