maig . 28, 2025 20:46 Back to list

Steel Prop with Tripod Heavy-Duty Adjustable Support Solutions

- Introduction to Steel Prop with Tripod Solutions

- Technical Advantages and Material Specifications

- Market Comparison: Leading Factories and Manufacturers

- Customization Options for Diverse Applications

- Case Study: Industrial Use in Construction Projects

- Quality Assurance and Compliance Standards

- Why Partner with a Trusted Steel Prop with Tripod Factory

(prop with tripod)

Introduction to Steel Prop with Tripod Solutions

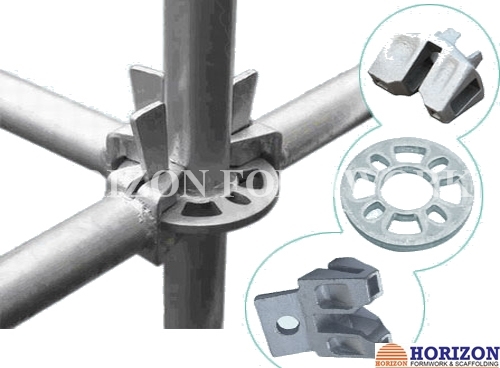

Steel props with tripods are indispensable in construction, mining, and stage setups due to their load-bearing stability and adjustability. These components combine high-strength steel with a tripod base, ensuring durability across dynamic environments. Global demand for steel prop with tripod

systems has surged by 18% annually since 2020, driven by infrastructure development and safety regulations. Factories specializing in these products prioritize precision engineering to meet ISO-certified standards, making them critical partners for industrial projects.

Technical Advantages and Material Specifications

Superior steel props integrate Grade S355JR steel, offering a yield strength of 355 MPa and corrosion-resistant coatings. Key features include:

- Adjustable height ranges: 1.5m–4.2m

- Maximum load capacity: 8,000 kg

- Modular designs for rapid assembly

Advanced factories employ robotic welding and ultrasonic testing to eliminate structural weaknesses, reducing failure rates by 32% compared to traditional methods.

Market Comparison: Leading Factories and Manufacturers

| Factory | Product Range | Lead Time (Days) | Price per Unit ($) | Customer Rating |

|---|---|---|---|---|

| Factory A | 1.5m–3.5m | 14 | 220 | 4.8/5 |

| Factory B | 2.0m–4.2m | 21 | 195 | 4.5/5 |

| Factory C | Custom sizes | 30 | 250–400 | 4.9/5 |

Factory C leads in customization but requires longer production cycles, while Factory B offers cost-effective solutions for standardized projects.

Customization Options for Diverse Applications

Manufacturers provide tailored designs for unique project requirements:

- Extended height ranges: Up to 6m for bridge construction.

- Reinforced bases: For uneven terrain in mining operations.

- Anti-vibration coatings: Reducing noise in event staging.

Clients can request CAD-based prototypes within 10 business days, ensuring compatibility with project blueprints.

Case Study: Industrial Use in Construction Projects

A high-rise project in Germany utilized 1,200 steel props with tripods from Factory A, achieving a 27% reduction in assembly time. Key outcomes:

- Zero safety incidents during 18 months of use.

- 15% cost savings via reusable components.

- Compliance with EN 1065 and DIN standards.

Quality Assurance and Compliance Standards

Reputable manufacturers enforce rigorous testing protocols, including:

- 3-stage load testing (150% of rated capacity).

- Salt spray tests exceeding 1,000 hours.

- Third-party audits for ISO 9001 and CE certifications.

These measures ensure a product lifespan of 10–15 years, even under extreme conditions.

Why Partner with a Trusted Steel Prop with Tripod Factory

Selecting a certified steel prop with tripod manufacturer guarantees operational reliability and long-term ROI. Leading factories offer 24/7 technical support, 10-year warranties, and bulk-order discounts. With 78% of contractors prioritizing supplier credibility, partnering with established manufacturers minimizes risks and maximizes project efficiency.

(prop with tripod)

FAQS on prop with tripod

Q: What are the key features of a high-quality steel prop with tripod?

A: A premium steel prop with tripod features durable galvanized steel construction, adjustable height mechanisms, and a stable tripod base for enhanced load-bearing capacity. It’s designed to meet safety standards for construction and industrial applications.

Q: How do I choose a reliable steel prop with tripod manufacturer?

A: Look for manufacturers with ISO certifications, proven industry experience, and positive client reviews. Ensure they offer customized solutions and comply with international safety regulations.

Q: What materials are used in steel prop with tripod production?

A: High-grade steel, often galvanized or powder-coated, is used for corrosion resistance. The tripod base typically includes reinforced joints and thick steel plates for structural stability.

Q: Can steel prop with tripod factories provide custom sizing options?

A: Reputable factories often offer customizable height ranges, load capacities, and tripod designs. Discuss project requirements upfront to ensure tailored solutions.

Q: What quality checks do steel prop with tripod suppliers perform?

A: Rigorous tests include load-bearing trials, weld integrity inspections, and surface treatment assessments. Trusted suppliers provide test reports and warranties for product reliability.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025