Flex-H20 slab formwork

Description

In combination with steel props, tripod, fork head and plywood, the H20 timer beams provide flexible and cost-effective slab formwork for any floor-plan, slab thickness and storey height.

The steel prop is simply set in the open area and secured through the locking pin with a gentle blow of the hammer.

The tripod makes it quite simple to set up the steel props during erection. The flexibly folding legs of the tripod permit an optimal fit, even in the corners of the structure. The tripod can be used with all types of props.

Formwork striking is made easier by lowering the H20 beam and plywood by releasing the adjustment nut of the steel props. With the space which results from the first lowering and by tilting the timber beams, the shuttering material can be systematically removed.

Advantages

1.Very few components make it easy and fast to erect. Props, timber beam H20, tripod and head jack are the main components.

2.As a quite flexible slab formwork system, Flex-H20 slab formwork can fit various floor layouts. It also can be used for different floor height combing with other shoring systems.

3.Perimeter and shaft protection with handrails.

4. Can match well with Euro formwork systems.

|

Components |

Diagram / photo |

Specification / description |

|

Timber beam H20 |

|

Water proof treated Height: 200mm Width: 80mm Length: as per table size |

|

Floor Props |

|

Galvanized As per proposal design HZP 20-300, 15.0kg HZP 20-350, 16.8kg HZP 30-300, 19.0kg HZP 30-350, 21.5kg |

|

Fork head H20 |

|

Galvanized Length: 220mm Width: 145mm Height: 320mm |

|

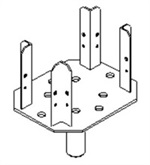

Folding tripod |

|

Galvanized For holding floor props 8.5kg/pc |

|

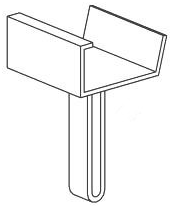

Supporting head |

|

Helps to attach an additional prop to the H20 beam 0.9kg/pc |